Napenjalniki in jermenice so sestavni deli pri vzdrževanju zmogljivosti in učinkovitosti motornih sistemov. Napenjalniki, ki so posebej zasnovani za uravnavanje in prilagajanje napetosti jermenov ali verig, zagotavljajo, da te komponente ostanejo pravilno poravnane z jermenicami ali zobniki. Ta natančna poravnava je ključnega pomena, saj zmanjšuje obrabo, zmanjšuje izgubo moči in zagotavlja učinkovit prenos moči po celotnem sistemu motorja.

Koluti z jermenicami imajo pomembno vlogo pri vodenju in vzdrževanju ustrezne napetosti jermenov dodatnega pogona motorja. Njihova glavna naloga je natančno vodenje jermenov in vzdrževanje pravilne napetosti. Z opravljanjem teh funkcij jermenice jermenic pomembno prispevajo k nemotenemu delovanju pomožnega pogonskega sistema motorja. Posledica tega so manjši hrup in vibracije, kar izboljša splošno zmogljivost motorja.

Pri napenjalcih je na voljo več vrst, ki so primerne za različne načine uporabe:

Samodejni napenjalci: Ti napenjalci se samodejno prilagajajo glede na razmere v sistemu ali z mehanskimi sredstvi, kot so vzmetni mehanizmi. Zasnovani so tako, da vzdržujejo optimalno napetost, ne da bi bilo potrebno ročno posredovanje, zato so idealni za aplikacije, kjer je koristno samodejno prilagajanje.

Ročni napenjalci: Za razliko od avtomatskih napenjalnikov je treba ročne napenjalnike za nastavitev ustrezne napetosti nastaviti ročno. To se običajno izvede z vijaki ali drugimi ročnimi mehanizmi. Čeprav omogočajo bolj praktičen pristop k nastavitvi napetosti, lahko zahtevajo redne preglede in nastavitve glede na obrabo in delovanje sistema.

Hidravlični ali pnevmatski napenjalniki: Uporabljajo se v zahtevnejših aplikacijah, kjer je ključnega pomena natančen in dosleden nadzor napetosti. Pogosto se uporabljajo v težkih strojih ali aplikacijah z visoko hitrostjo, kjer običajni napenjalci morda ne zagotavljajo potrebne natančnosti ali učinkovitosti.

Za različne potrebe so na voljo tudi različne vrste jermenic:

Gladke jermenice: To so preproste jermenice z gladko površino, po kateri teče jermen. Uporabljajo se v primerih, ko ni potreben dodaten oprijem, zato so primerne za aplikacije z minimalnimi zahtevami glede oprijema jermena.

Vrezane jermenice: Prosti jermenice z utori imajo utore, ki se ujemajo s profilom reber jermena. Uporabljajo se v sistemih serpentinskega jermena, kjer sta za učinkovit prenos moči potrebna natančna poravnava in oprijem. Utori pomagajo zagotoviti, da jermen ostane v pravilnem položaju in ohranja učinkovit prenos moči.

Če poznate različne vrste napenjalnikov in jermenic ter njihove specifične uporabe, se lahko na podlagi informacij odločite, katere komponente najbolje ustrezajo potrebam vašega motornega sistema. Vsaka vrsta napenjalnika in jermenice ima svoje prednosti in je zasnovana tako, da izpolnjuje posebne zahteve ter zagotavlja optimalno delovanje in dolgo življenjsko dobo pogonskega sistema vašega motorja.

Uporaba v avtomobilskih sistemih:

- Sistemi zobatega jermena: V motorjih z zobatimi jermeni se jermenice uporabljajo za vodenje jermena in vzdrževanje napetosti med ročično in odmično gredjo(-ami), kar zagotavlja natančno sinhronizacijo sestavnih delov motorja.

- Dodatni pogonski sistemi: Jermenice so v sistemih, ki poganjajo komponente, kot so vodna črpalka, črpalka servoojačevalnika, kompresor klimatske naprave in alternator. Te komponente so ključnega pomena za delovanje vozila in udobje potnikov.

Inženirska odličnost

- Natančna proizvodnja: Vsaka jermenica je izdelana z naprednimi stroji CNC, ki zagotavljajo natančne specifikacije in tolerance. Ta natančnost zagotavlja popolno prileganje in optimalno delovanje v vozilih Buick, Chevrolet in Cadillac.

- Inovativno oblikovanje: Serija z naprednimi konstrukcijskimi izboljšavami zagotavlja boljšo poravnavo jermena in dosledno napetost, kar preprečuje zdrs in zmanjšuje obrabo.

Kakovost materiala

- Vrhunski materiali: Te jermenice so izdelane iz vrhunskih materialov, kot so ojačano jeklo in napredni polimeri, zato so odporne na ekstremne pogoje in zagotavljajo odlično odpornost na vročino, korozijo in mehanske obremenitve.

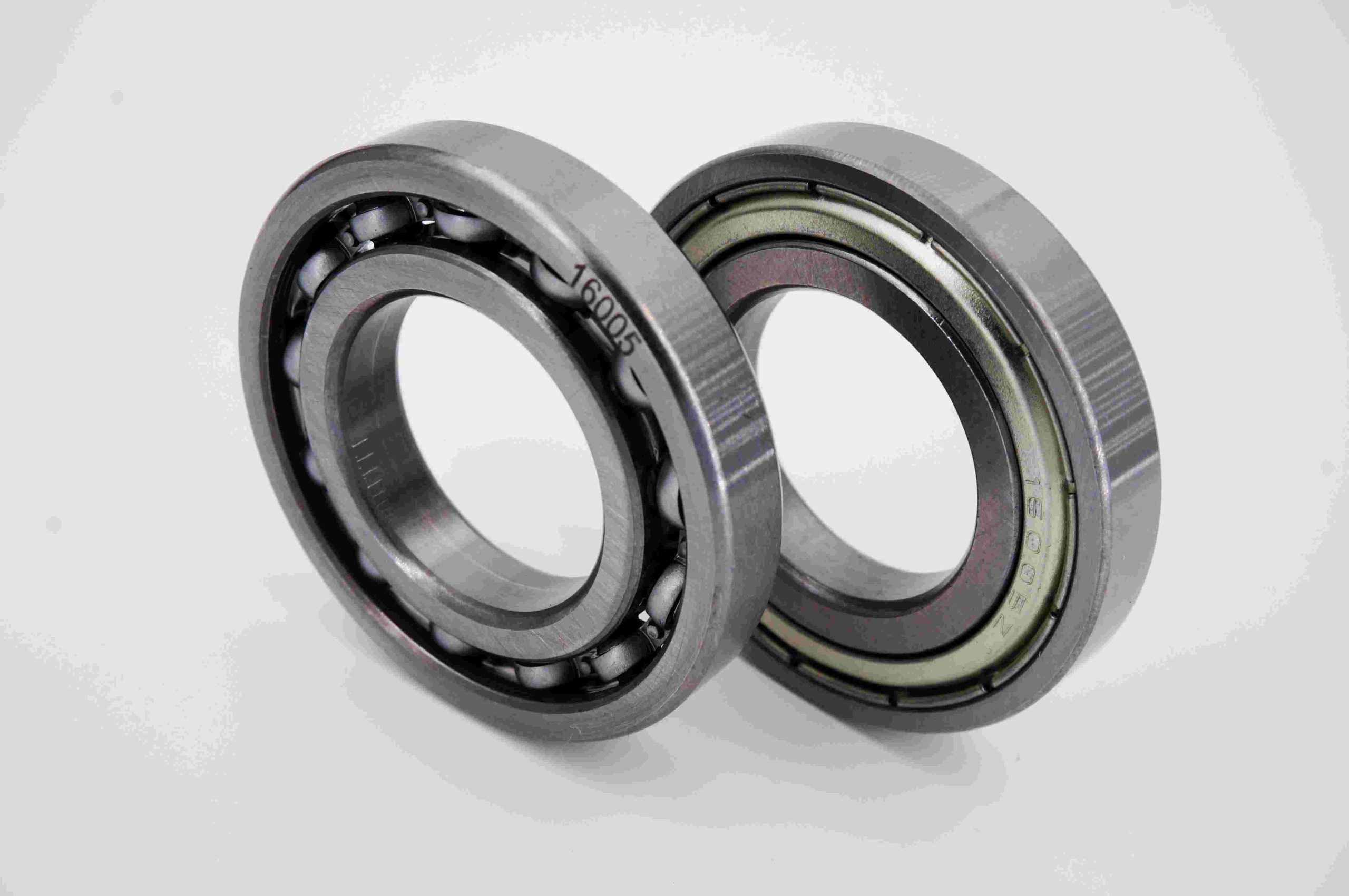

- Zatesnjeni ležaji: Te jermenice z visokokakovostnimi zatesnjenimi ležaji zagotavljajo gladko in tiho delovanje, hkrati pa ščitijo pred vdorom umazanije in vlage ter tako podaljšujejo življenjsko dobo komponent.

Prednosti delovanja

- Povečana vzdržljivost: Jermenice serij Buick, Chevrolet in Cadillac z vrhunskimi materiali in konstrukcijskimi tehnikami zagotavljajo izjemno vzdržljivost tudi v težkih delovnih pogojih.

- Optimalna napetost: Napenjalna jermenica vzdržuje pravilno napetost pogonskega jermena, kar je ključnega pomena za učinkovito delovanje motorja. S tem preprečuje, da bi jermen zdrsnil ali postal preveč napet, kar zmanjšuje njegovo obrabo.

- Nemoteno delovanje: Jermenica zagotavlja, da se pogonski jermen gladko premika po sestavnih delih motorja, kar zmanjšuje hrup in vibracije ter zagotavlja tišjo vožnjo.

Načelo delovanja

- Napenjalna jermenica: Napenjalna jermenica deluje na pogonski jermen z nadzorovano silo in vzdržuje pravilno napetost, ki je potrebna za optimalno delovanje. Napenjalna vzmet se prilagaja raztezanju jermena in vibracijam motorja ter tako zagotavlja stalno napetost. To preprečuje drsenje jermena in zagotavlja učinkovit prenos moči na različne sestavne dele motorja.

- Kolutiček z navijalko: Kretnica vodi in podpira pogonski jermen ter zagotavlja njegovo gladko gibanje po sestavnih delih motorja. Deluje kot usmerjevalna točka, vzdržuje pravilno pot in poravnavo jermena, zmanjšuje trenje in obrabo ter tako prispeva k splošni učinkovitosti in dolgi življenjski dobi sistema pogonskega jermena.