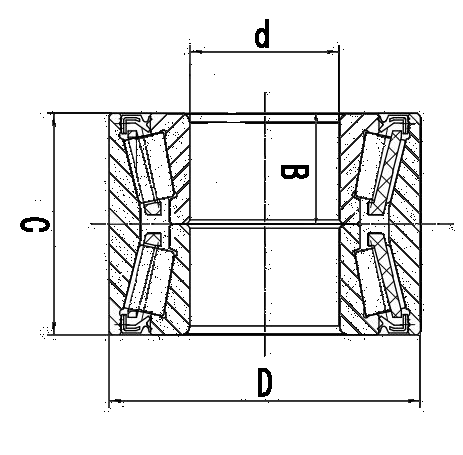

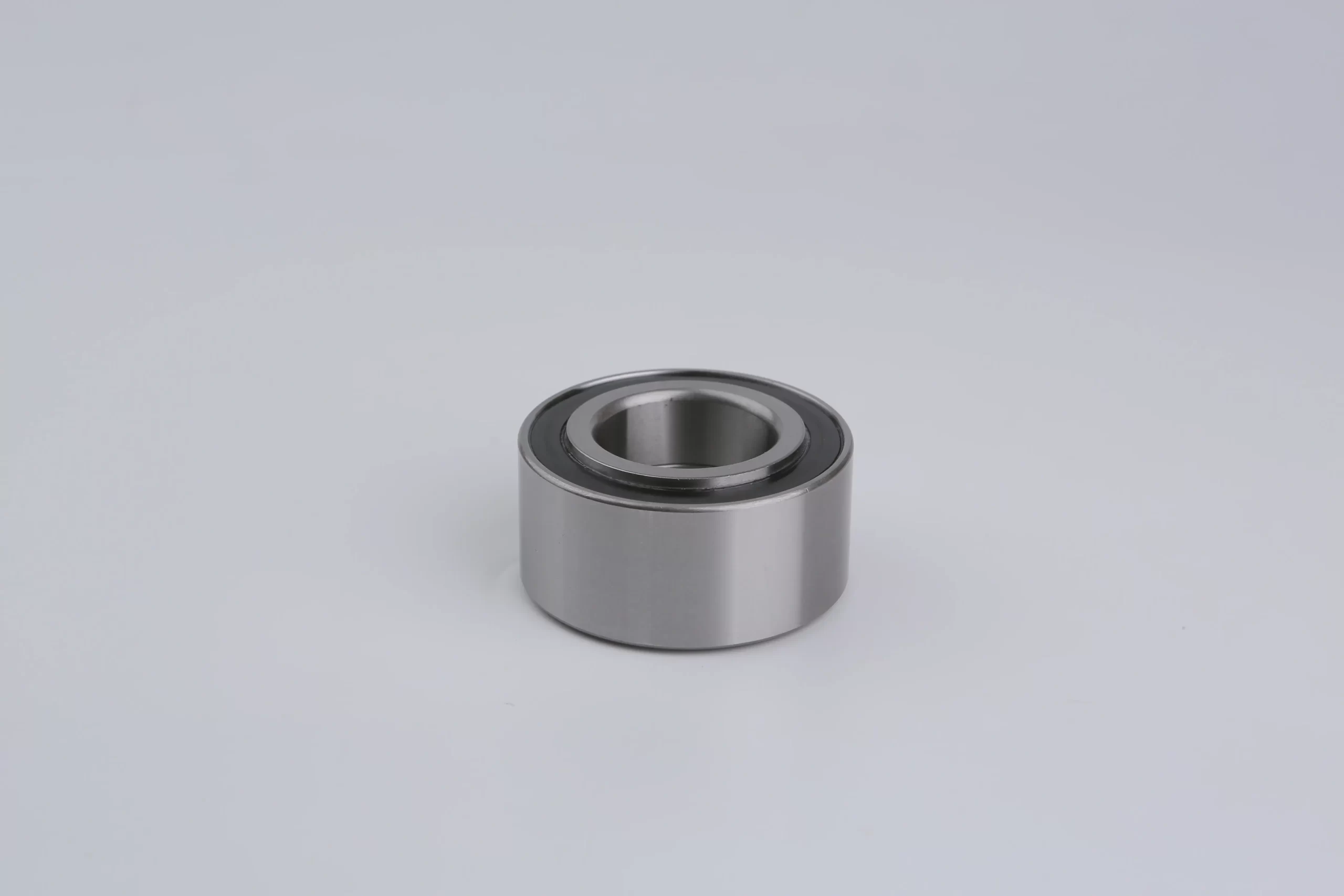

Konštrukcia a štruktúra dvojradových kuželíkových ložísk

Kužeľové valčeky

Dvojradové kuželíkové ložiská sú skonštruované tak, aby zvládali značné radiálne a axiálne zaťaženie v oboch smeroch, čo z nich robí kľúčové ložiská pre aplikácie s vysokými nárokmi. Valčeky sú usporiadané v dvoch radoch, pričom každý z nich je umiestnený s presným kužeľom, ktorý uľahčuje optimálne rozloženie zaťaženia. Táto konštrukcia minimalizuje namáhanie valčekov a predlžuje životnosť ložiska.

- Dizajn valca: Zúžený tvar valčekov im umožňuje zvierať s dráhami väčší uhol. Tým sa zabezpečuje rovnomerné rozloženie zaťaženia a zvyšuje sa schopnosť ložiska prenášať značné sily. Konštrukcia tiež pomáha znižovať koncentráciu napätia, čo vedie k vyššej životnosti.

Vnútorné a vonkajšie krúžky

Vnútorný a vonkajší krúžok, známe aj ako vnútorné a vonkajšie ozubené kolieska, tvoria základné konštrukčné prvky ložiska. Tieto krúžky sú starostlivo skonštruované tak, aby dokonale priliehali ku kužeľovým valčekom, zabezpečovali efektívny prenos zaťaženia a minimalizovali opotrebovanie.

- Materiál prsteňa: Krúžky sa zvyčajne vyrábajú z vysokopevnostnej ocele a sú tepelne spracované, aby sa zvýšila ich tvrdosť a odolnosť proti opotrebovaniu. Tento výber materiálu a jeho úprava sú rozhodujúce pre zachovanie výkonu ložiska pri veľkom zaťažení a v náročných podmienkach.

Retainer

Držiak alebo klietka zohráva dôležitú úlohu pri zachovaní funkčnosti ložiska. Rovnomerne rozmiestňuje valčeky a zabraňuje ich vzájomnému kontaktu, čo je nevyhnutné pre hladkú prevádzku a zníženie trenia.

- Funkčnosť klietky: Držiak pomáha predchádzať vychýleniu a nesprávnemu nastaveniu valčekov, ktoré môže viesť k predčasnému opotrebovaniu alebo poruche ložiska. Jeho konštrukcia zabezpečuje, že každý valček pracuje nezávisle vo svojom určenom priestore, čím sa zvyšuje celková účinnosť.

Tesnenia

Technológia tesnenia je integrovaná do konštrukcie, aby chránila ložisko pred vonkajšími nečistotami, ako sú špina, voda a úlomky. Táto ochrana je nevyhnutná na zachovanie dlhodobého výkonu a predchádzanie predčasnému zlyhaniu ložiska.

- Typy tesnení: Pokročilé tesnenia sa používajú na udržanie mazív v ložisku a na jeho ochranu pred znečisťujúcimi látkami z okolia. Táto funkcia je kľúčová pre udržanie úrovne mazania a zabezpečenie bezproblémovej prevádzky ložiska počas celej jeho životnosti.

Použitie dvojradových kuželíkových ložísk

Náboje automobilových kolies

V automobilovom priemysle sa dvojradové kuželíkové ložiská bežne používajú v nábojoch kolies, kde poskytujú základnú podporu pre otáčanie kolies. Používajú sa v nábojoch predných aj zadných kolies, kde prenášajú značné radiálne a axiálne zaťaženie.

- Funkcia vo vozidlách: Tieto ložiská zabezpečujú plynulú prevádzku kolies a udržiavajú hmotnosť vozidla, pričom absorbujú sily, ktoré vznikajú počas jazdy. Vďaka svojej robustnej konštrukcii sú ideálne na použitie vo vozidlách s vysokým zaťažením.

Ťažké stroje

Okrem použitia v automobilovom priemysle sú tieto ložiská neoddeliteľnou súčasťou ťažkých strojov a priemyselných zariadení. Vďaka svojej schopnosti zvládnuť značné zaťaženie sú vhodné na rôzne aplikácie v strojoch, ktoré si vyžadujú vysoký výkon a spoľahlivosť.

- Priemyselné aplikácie: V ťažkých strojoch sa dvojradové kuželíkové ložiská používajú v prevodovkách, dopravníkových systémoch a iných zariadeniach, kde je rozhodujúca spoľahlivá podpora zaťaženia a trvanlivosť. Ich vysoká nosnosť a odolnosť v náročných podmienkach z nich robia nepostrádateľné.

Opatrenia na kontrolu kvality

Výber a testovanie materiálov

- Kontrola surovín: Vykonávame dôkladné kontroly a testy surovín, aby sme zabezpečili, že spĺňajú prísne normy kvality. To zahŕňa analýzu chemického zloženia a mechanické skúšky na overenie vlastností materiálu.

Presná výroba

- Rozmerová presnosť: Naše výrobné procesy využívajú pokročilé techniky na zaručenie presných rozmerov a tolerancií. Automatizované stroje a pravidelná kalibrácia zabezpečujú jednotnosť a konzistenciu všetkých výrobných dávok.

Komplexné testovanie

- Viacstupňové testovanie: Ložiská sa podrobujú rozsiahlemu testovaniu vrátane hodnotenia presnosti rozmerov, nosnosti a rýchlosti otáčania. Testy odolnosti simulujú rôzne prevádzkové podmienky, aby sa zabezpečila dlhodobá spoľahlivosť a výkonnosť.

Certifikácia a dodržiavanie predpisov

- Dodržiavanie noriem: Dodržiavame medzinárodné normy kvality, ako je ISO 9001, čo dokazuje náš záväzok udržiavať vysokokvalitné výrobné procesy. Pravidelné audity a revízie zabezpečujú trvalý súlad s priemyselnými normami.

Spätná väzba od zákazníkov a neustále zlepšovanie

- Integrácia spätnej väzby: Aktívne zapracovávame spätnú väzbu od zákazníkov s cieľom zlepšiť naše produkty a procesy. Náš záväzok neustáleho zlepšovania je hnacou silou výskumu, vývoja a inovácií v oblasti ložiskovej technológie.

Tipy na inštaláciu a údržbu

Správna inštalácia

- Nástroje a techniky: Používajte správne nástroje a dodržiavajte špecifikácie výrobcu týkajúce sa krútiaceho momentu a nastavenia, aby ste predišli poškodeniu. Vyhnite sa nadmernej sile, aby ste zabránili poškodeniu ložiska alebo súčiastky.

Pravidelné mazanie

- Kvalita maziva: Aplikujte odporúčaný typ a množstvo maziva a dbajte na to, aby bolo čisté a bez nečistôt. Pravidelne kontrolujte a dopĺňajte mazivo, aby ste udržali optimálny výkon.

Správne prispôsobenie a zarovnanie

- Kontroly vyrovnania: Uistite sa, že ložisko správne zapadá do puzdra a na hriadeľ. Pravidelne overujte zarovnanie pomocou presných nástrojov, aby ste zabránili nerovnomernému opotrebovaniu a predčasnému zlyhaniu.

Správne zaobchádzanie

- Manipulačná starostlivosť: S ložiskami manipulujte opatrne, aby ste predišli fyzickému poškodeniu počas prepravy a inštalácie. Používajte čisté rukavice, aby ste zabránili znečisteniu a zabránili pádu alebo nárazu ložiska.

Dodržiavaním týchto konštrukčných zásad, opatrení na kontrolu kvality a tipov na údržbu môžete zabezpečiť spoľahlivosť a výkon dvojradových kuželíkových ložísk v rôznych náročných aplikáciách.