Introducere

Polițe de întindere și de întindere fac parte integrantă din sistemul de transmisie cu curele pentru accesorii al oricărui motor auto. Ele joacă un rol crucial în menținerea tensiunii și alinierii corecte a curelelor, asigurând funcționarea eficientă a diferitelor accesorii ale motorului, cum ar fi alternatorul, pompa servodirecției și compresorul de aer condiționat. În ciuda importanței lor, aceste polițe sunt adesea trecute cu vederea în timpul întreținerii de rutină, ceea ce duce la uzură prematură, alunecarea curelei și chiar defectarea catastrofală a motorului.

Acest articol analizează importanța întreținerii scripeților întinzători și a scripeților întinzători, oferă îndrumări detaliate cu privire la modul de inspectare, întreținere și înlocuire a acestora și evidențiază potențialele consecințe ale neglijării acestor componente. Prin înțelegerea rolului și a întreținerii scripeților întinzători și de întindere, profesioniștii și pasionații de automobile pot prelungi semnificativ durata de viață a vehiculelor lor și pot evita reparațiile costisitoare.

Înțelegerea scripeților întinzători și a scripeților creiței

Înainte de a trece la practicile de întreținere, este esențial să înțelegeți funcția polițelor de tensionare și a celor de întindere în cadrul unui motor.

- Polei de tensionare: Poleiul întinzător este conceput pentru a aplica cantitatea corectă de tensiune curelei serpentine, asigurându-se că aceasta rămâne strânsă și în contact cu toate polițele accesoriilor motorului. Acest scripete este montat pe un braț încărcat cu arc care se reglează automat pe măsură ce cureaua se întinde în timp, menținând o tensiune constantă.

- Polei de transmisie: Pe de altă parte, poleiul de întindere servește drept ghidaj pentru cureaua serpentină, ajutând la dirijarea acesteia în jurul diferitelor componente ale motorului. Spre deosebire de scripetele întinzător, scripetele întinzător nu reglează tensiunea; funcția sa principală este de a oferi puncte suplimentare de contact pentru curea, asigurându-se că aceasta rămâne în poziție și funcționează fără probleme.

Ambele scripeți sunt supuși unei uzuri constante din cauza funcționării lor continue sub stres și temperaturi ridicate. Prin urmare, inspecția și întreținerea regulată sunt cruciale pentru a preveni defecțiunile care ar putea duce la probleme semnificative ale motorului.

Semne de probleme cu întinzătorul și scripetele

Recunoașterea semnelor de defectare a tensionatorului sau a scripetelui de întindere este primul pas în întreținerea eficientă. Simptomele comune includ:

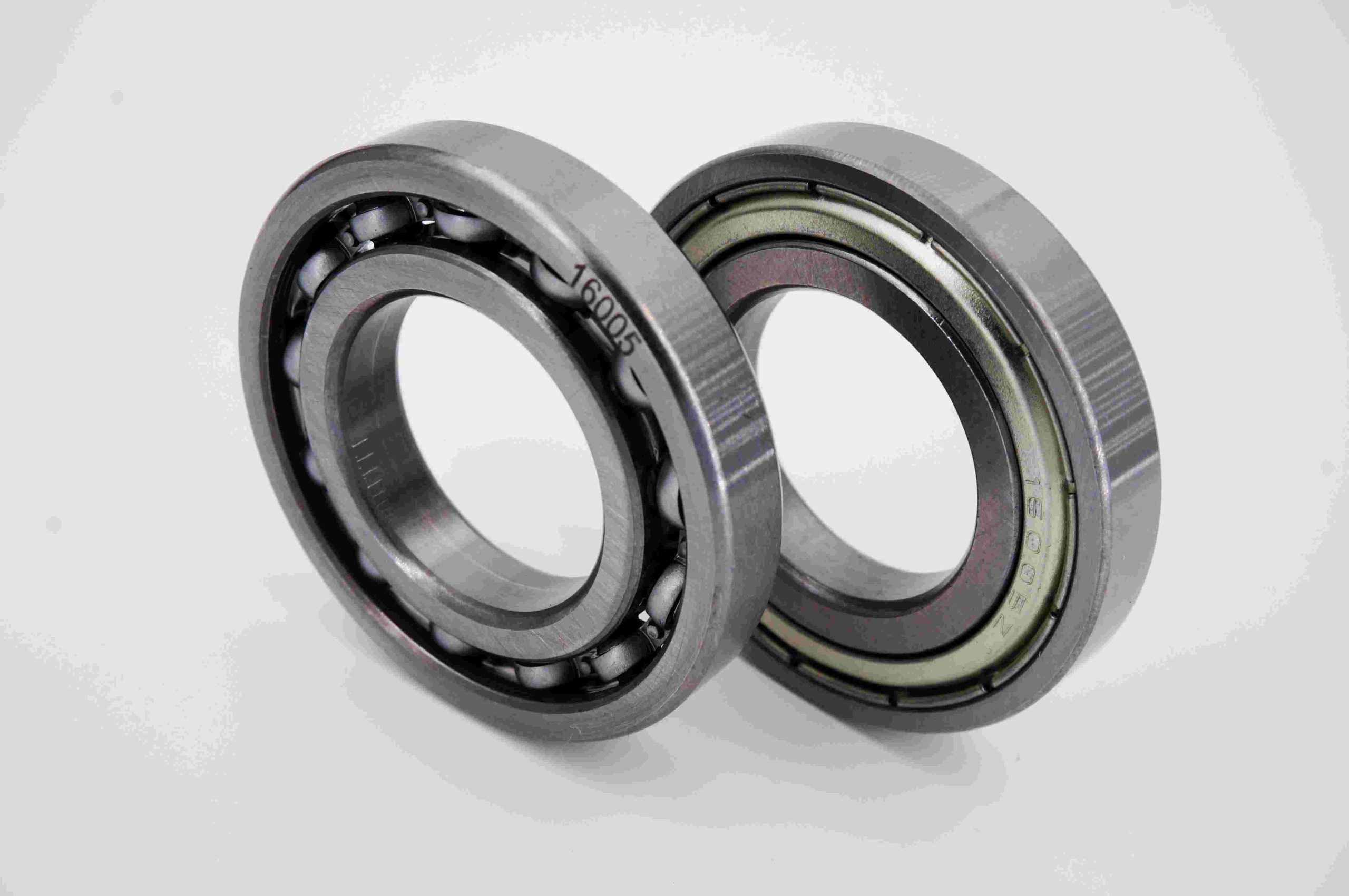

- Zgomot neobișnuit: Unul dintre cele mai evidente semne ale unei probleme cu scripeții este reprezentat de zgomotele neobișnuite care provin din compartimentul motorului. Un sunet de scârțâit, măcinat sau zăngănit indică adesea că rulmenții scripetelui sunt uzați sau deteriorați.

- Uzura centurii: Uzura excesivă sau neuniformă a curelei poate fi un semn că întinzătorul sau tamburul de întindere nu funcționează corect. Dacă cureaua pare uzată, crăpată sau glazurată, aceasta se poate datora unei tensiuni necorespunzătoare sau unei nealinieri cauzate de un scripete defect.

- Alunecarea centurii: Dacă cureaua serpentină alunecă de pe polițe sau nu reușește să mențină un contact adecvat, este posibil ca polița întinzătoare să nu asigure o tensiune adecvată. Acest lucru poate duce la o pierdere de putere la accesoriile motorului și la o posibilă defectare a curelei.

- Defecțiuni ale accesoriilor motorului: Un tensionator sau un tambur de întindere defect poate face ca cureaua serpentină să piardă contactul cu accesoriile motorului, ducând la funcționarea defectuoasă a unor componente precum alternatorul, pompa de servodirecție sau compresorul de aer condiționat.

- Uzură vizibilă pe scripete: Inspecția fizică a scripeților poate dezvălui semne vizibile de uzură, cum ar fi caneluri, fisuri sau deformări. Acestea sunt indicii clare că scripetele trebuie înlocuit.

Practici de întreținere a scripeților de întindere și a scripeților întinzători

Pentru a asigura longevitatea și buna funcționare a scripeților întinzători și a scripeților întinzători, întreținerea regulată este esențială. Mai jos sunt prezentate etapele cheie implicate în întreținerea acestor componente:

1. Inspecția periodică

Inspecția de rutină a polițelor de întindere și a celor de întindere trebuie să facă parte din fiecare program de întreținere a motorului. Este recomandabil să inspectați acești poliți de fiecare dată când este înlocuită cureaua serpentină sau de fiecare dată când există semne de probleme legate de curea.

- Inspecție vizuală: Căutați semne vizibile de uzură sau deteriorare pe polițe, cum ar fi fisuri, caneluri sau joc excesiv. Verificați, de asemenea, starea curelei serpentine, deoarece aceasta poate oferi indicii cu privire la starea scripeților.

- Verificarea zgomotului: Ascultați orice zgomote neobișnuite provenite de la polițe în timpul funcționării motorului. Sunetele de scârțâit sau de măcinat indică adesea rulmenți uzați.

- Test de tensiune: Pentru scripeții cu tensor, verificați tensiunea curelei serpentine. O curea prea slăbită sau prea strânsă poate sugera că tensionatorul nu funcționează corect.

2. Lubrifierea

Deși cele mai multe polițe de întindere și de întindere moderne sunt prevăzute cu rulmenți etanși care nu necesită lubrifiere, modelele mai vechi pot beneficia de lubrifiere ocazională pentru a reduce frecarea și a preveni uzura prematură. Consultați întotdeauna instrucțiunile producătorului pentru cerințele specifice de lubrifiere.

3. Înlocuirea centurii

Cureaua serpentină trebuie înlocuită în conformitate cu intervalul recomandat de producător, de obicei la fiecare 60.000-100.000 de mile. Atunci când se înlocuiește cureaua, este o practică bună să se inspecteze și, dacă este necesar, să se înlocuiască și polițele de întindere și cele de întindere. O curea uzată poate exercita o presiune suplimentară asupra acestor polițe, accelerând uzura acestora.

4. Înlocuirea scripeților

Polițele de întindere și de întindere trebuie înlocuite dacă prezintă semne de uzură, deteriorare sau funcționare defectuoasă. Este important să utilizați piese de schimb de înaltă calitate, care îndeplinesc sau depășesc specificațiile producătorului. Este posibil ca scripeții de calitate inferioară să nu asigure tensiunea sau durabilitatea necesare, ducând la defecțiuni premature.

- Înlocuirea scripetelui de tensionare: Pentru a înlocui tamburul de tensionare, mai întâi, slăbiți tensiunea de pe cureaua serpentină prin rotirea brațului de tensionare. Scoateți poleiul vechi și instalați-l pe cel nou, asigurându-vă că este aliniat corect. Reaplicați tensiunea la curea și verificați alinierea corectă.

- Înlocuirea poleiului de transmisie: Înlocuirea scripetelui de întindere este similară cu cea a scripetelui de tensionare. Pur și simplu scoateți poleiul vechi și instalați-l pe cel nou, asigurându-vă că este bine fixat și aliniat corect cu cureaua.

5. Verificarea alinierii

Alinierea corectă a curelei serpentină este esențială pentru funcționarea eficientă a sistemului de acționare a accesoriilor motorului. Nealinierea poate cauza uzura excesivă a curelei și a scripeților, ducând la defectarea prematură.

- Instrumente de aliniere: Sunt disponibile instrumente speciale pentru verificarea alinierii curelei serpentine. Aceste instrumente pot ajuta la identificarea oricăror probleme de nealiniere și pot asigura poziționarea corectă a scripeților.

- Corectarea nealinierii: Dacă se detectează o nealiniere, este posibil să fie necesară ajustarea poziției scripeților sau înlocuirea componentelor uzate care cauzează nealinierea.

6. Monitorizarea performanței

După înlocuirea sau întreținerea tensionatorului și a scripeților, este important să monitorizați performanța sistemului de acționare a accesoriilor motorului. Acordați atenție oricăror zgomote neobișnuite, uzurii curelei sau disfuncționalităților accesoriilor, deoarece acestea ar putea indica probleme subiacente care trebuie abordate.

Consecințele neglijării întreținerii scripeților

Neîntreținerea corespunzătoare a scripeților de tensionare și a celor de întindere poate duce la o serie de probleme, inclusiv:

- Eșecul centurii: Un scripete defect poate face ca cureaua serpentină să alunece, să se sfâșie sau să se rupă, ducând la o pierdere de putere pentru accesoriile esențiale ale motorului.

- Defecțiuni ale accesoriilor: Un scripete uzat sau deteriorat poate face ca cureaua să piardă contactul cu accesoriile motorului, ducând la funcționarea defectuoasă a componentelor critice precum alternatorul, pompa servodirecției sau compresorul de aer condiționat.

- Supraîncălzirea motorului: În unele cazuri, un scripete defect poate cauza oprirea funcționării pompei de apă, ceea ce duce la supraîncălzirea motorului și la deteriorarea potențială a motorului.

- Creșterea costurilor de reparații: Neglijarea întreținerii scripeților poate duce la reparații mai extinse și mai costisitoare, inclusiv înlocuirea întregului sistem de acționare a accesoriilor sau chiar deteriorarea motorului.

Concluzie

Poleiurile de întindere și de întindere pot fi componente mici, dar rolul lor în funcționarea eficientă a sistemului de acționare a accesoriilor unui motor nu poate fi supraestimat. Inspecția regulată, întreținerea și înlocuirea la timp a acestor polițe sunt esențiale pentru a asigura longevitatea curelei serpentine și funcționarea corespunzătoare a accesoriilor motorului.

Urmând practicile de întreținere descrise în acest articol, profesioniștii și pasionații de automobile pot evita capcanele comune asociate cu defecțiunile polielilor, pot reduce riscul unor reparații costisitoare și își pot menține vehiculele în stare de funcționare fără probleme. Nu uitați, un sistem de scripeți bine întreținut nu numai că îmbunătățește performanța motorului, dar contribuie și la fiabilitatea și siguranța generală a vehiculului dumneavoastră.