Products

Product Categories

Featured products

The double row tapered roller wheel hub bearing, we referred to as the DU series in the context of wheel hub bearings, is a critical component in the automotive industry. These bearings are designed to handle both radial and axial loads, providing reliable performance and durability.

- Our Advantages:

- High Load Capacity: The double row configuration allows these bearings to handle higher loads compared to single row bearings, making them ideal for demanding applications.

- Durability: The robust design and high-quality materials ensure long-lasting performance, even under challenging conditions.

- Precision: The precise engineering of the inner and outer rings, along with the tapered rollers, ensures smooth and efficient operation.

- Reduced Maintenance: The advanced sealing technology and pre-lubricated design reduce the need for regular maintenance, saving time and costs.

Tensioner & Idler Pulley - Mitsubishi & Subaru series

Tensioner and idler pulleys are essential components in the belt drive systems of Mitsubishi and Subaru vehicles. They ensure the proper tension and alignment of the serpentine and timing belts, which drive various engine accessories.

Proper maintenance of tensioner and idler pulleys ensures the reliable operation of the engine’s belt drive system, contributing to the overall performance and longevity of Mitsubishi and Subaru vehicles.

Upgrade your Mitsubishi or Subaru with our high-quality Tensioner and Idler Pulley which crafted with precision and advanced moulds.

A tensioner, in mechanical engineering and automotive applications, refers to a device or mechanism used to maintain or adjust the tension of a belt, chain, or similar flexible element. Its primary function is to ensure that the belt or chain remains taut and properly aligned, which is crucial for the efficient operation and longevity of various systems.

Idler pulleys are primarily used to route and maintain proper tension in the engine's accessory drive belts. By guiding the belts and maintaining tension, idler pulleys contribute to smooth operation of the engine's accessory drive system, thereby reducing noise and vibrations.

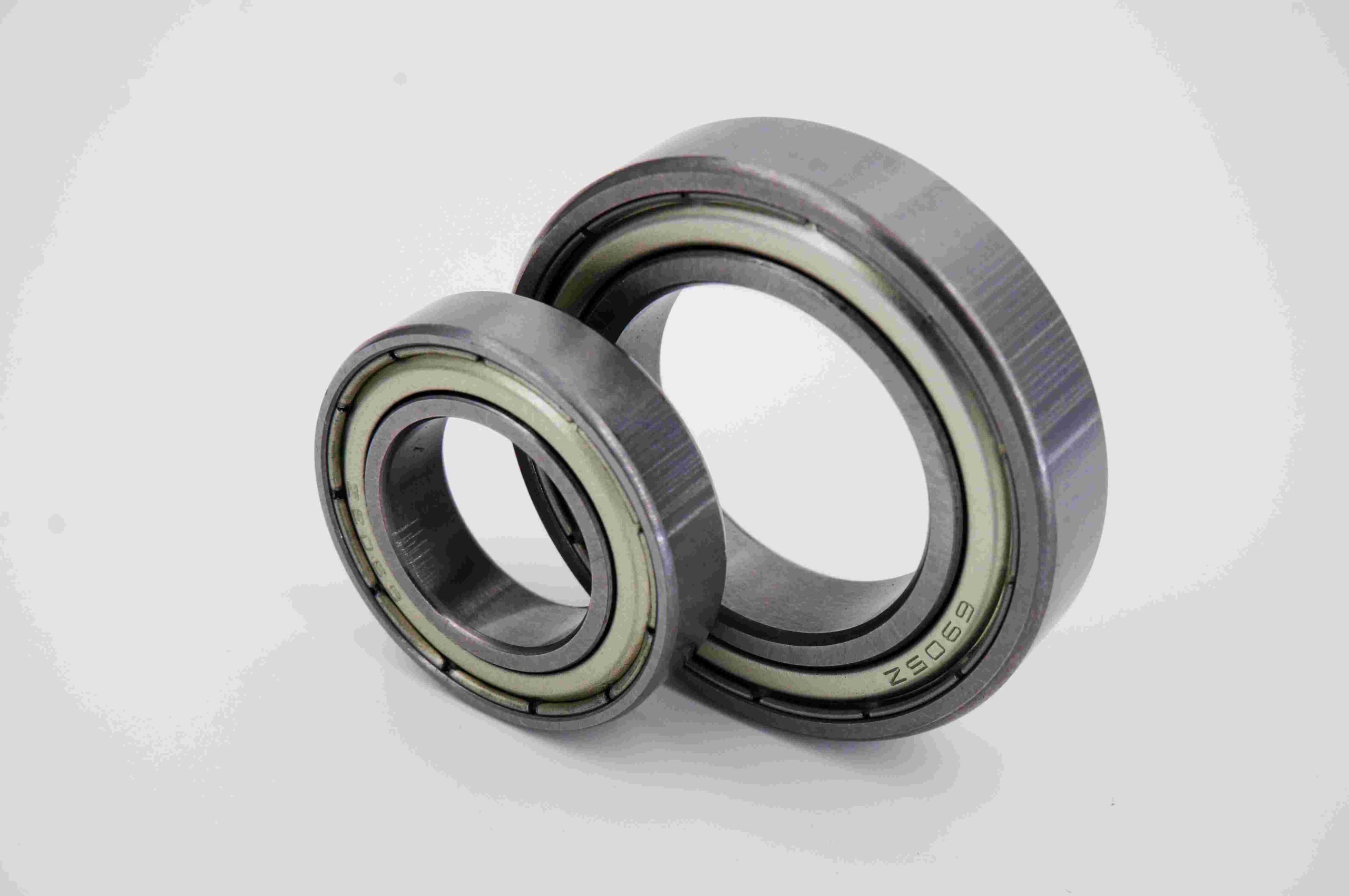

Deep Groove Ball Bearings of 6900 Series

6900 Series (also used to be known as 619 series) Deep groove ball bearing is a common type of bearing characterized by its ability to handle both radial and axial loads.

Tensioner & Idler Pulley - Great Wall Cars Series

Welcome to Vankv, where quality meets reliability in automotive solutions.

Our Tensioner & Idler Pulley series for Great Wall cars sets the standard for performance and durability.

To optimize engine belt systems, these precision-engineered components ensure smooth operation and extended lifespan for vehicle.

Our products not only meet but exceed industry standards, delivering exceptional performance and durability.

Whether you're replacing worn-out parts or upgrading for enhanced reliability, trust in our expertise to elevate your driving experience.

Deep Groove Ball bearings of 6200 Series

A mechanical component used to reduce friction between rotating parts.

It features two concentric rings (inner and outer) with a series of steel balls in between, housed in deep grooves that run along the rings' inner surfaces.

This design allows the bearing to support both radial loads (perpendicular to the shaft) and axial loads (along the shaft) while maintaining high rotational speed and efficiency.

They are widely utilized in applications such as electric motors, automotive components, and industrial equipment due to their durability and smooth performance.

By using and maintaining deep groove ball bearings properly, you can enhance the performance and reliability of your machinery and devices, ensuring long-lasting and efficient operation.

Recent Articles

Deep Groove Ball bearings of 6200 Series

A mechanical component used to reduce friction between rotating parts.

It features two concentric rings (inner and outer) with a series of steel balls in between, housed in deep grooves that run along the rings' inner surfaces.

This design allows the bearing to support both radial loads (perpendicular to the shaft) and axial loads (along the shaft) while maintaining high rotational speed and efficiency.

They are widely utilized in applications such as electric motors, automotive components, and industrial equipment due to their durability and smooth performance.

By using and maintaining deep groove ball bearings properly, you can enhance the performance and reliability of your machinery and devices, ensuring long-lasting and efficient operation.

Deep Groove Ball Bearings of 6900 Series

6900 Series (also used to be known as 619 series) Deep groove ball bearing is a common type of bearing characterized by its ability to handle both radial and axial loads.

Deep Groove Ball Bearings of 6800 Series

6800 Series (also used to be known as 618 series) deep groove ball bearing is a widely used bearing type known for its simple and robust design.

The "deep groove" refers to the close proximity of the balls to the raceways, which allows for higher load capacities and smoother operation.

This design allows the bearing to support high radial loads and moderate axial loads in both directions.

These bearings are prized for their high-speed operation, quiet performance, and ability to function reliably in a variety of applications, including industrial machinery, automotive systems, and household devices.

These bearings are versatile, reliable, and commonly used in applications ranging from household appliances to industrial machinery.

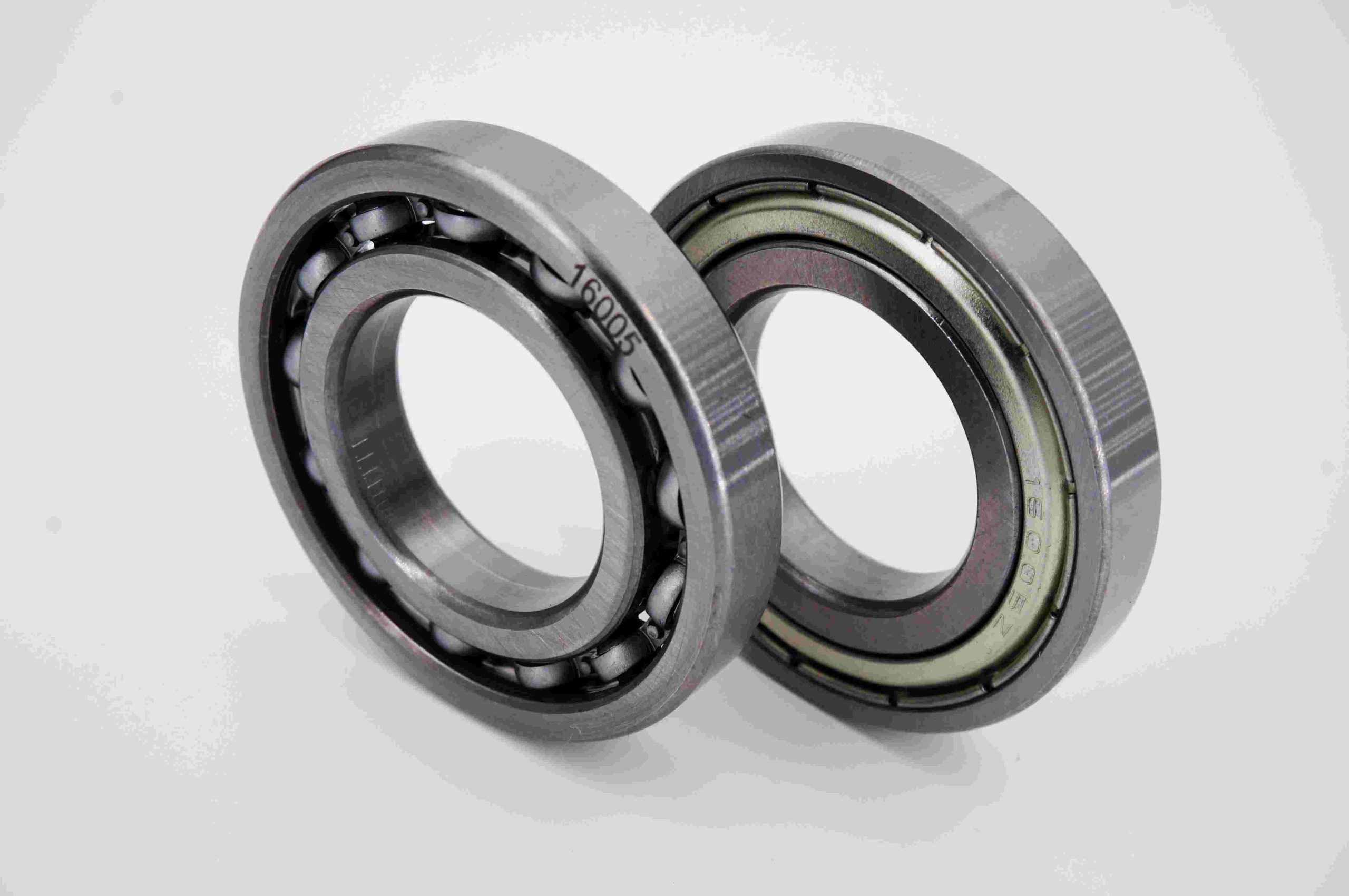

Deep Groove Ball Bearing 16000 Series

The Deep Groove Ball Bearing 16000 Series offers several advantages:

- High Load Capacity: Capable of handling both radial loads and axial loads.

- High Speed: Suitable for high-speed operations due to low friction and minimal heat generation.

- Durability: Long service life with robust construction.

- Versatility: Applicable in a wide range of industries and machines.

- Low Maintenance: Requires minimal lubrication and maintenance.

- Smooth Operation: Provides quiet and efficient performance.

Applications:

- Electric Motors: Ensure smooth and efficient operation.

- Automotive: Used in wheels, transmissions, and other components.

- Industrial Machinery: Found in pumps, fans, and various equipment.

- Household Appliances: Common in washing machines, fans, and other devices.

DAC wheel hub bearings (or Double Angular Contact ball bearing) are critical components in the automotive industry, used primarily in the wheel hubs of cars, trucks, and other vehicles.

They are designed to provide high performance, durability, and reliability under various driving conditions, ensuring smooth wheel rotation and supporting the vehicle’s weight.

This integrated design simplifies installation and maintenance, enhances performance, and contributes to the overall safety and efficiency of the vehicle.