Deep groove ball bearings are integral components known for their robust design, versatility, and ability to support various loads while maintaining high-speed performance and reliability across diverse applications.

By using and maintaining deep groove ball bearings properly, you can enhance the performance and reliability of your machinery and devices, ensuring long-lasting and efficient operation.

Our factory ensures deep groove ball bearing quality through meticulous steps: rigorous material selection, precise machining, heat treatment for durability, thorough inspections, and careful packaging for reliability.

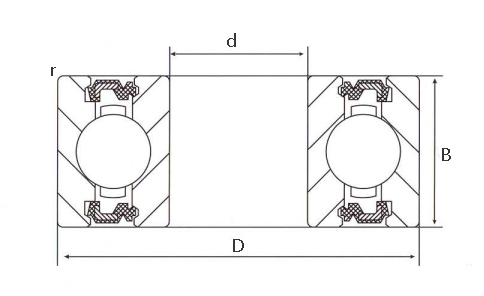

A deep groove ball bearing is a fundamental type of rolling-element bearing characterized by its ability to support both radial and axial loads. Here’s a detailed breakdown of its construction and functionality:

- Construction:

Inner and Outer Rings: The bearing comprises an inner ring that fits onto the shaft and an outer ring that surrounds the rotating assembly.

Raceway Grooves: Both rings feature deep, continuous raceway that facilitate the movement of steel balls.

Steel Balls: Positioned between the inner and outer rings, these balls are evenly spaced and roll along the raceway grooves. - Functionality:

Load Capacity: The deep raceway grooves enable the bearing to carry radial loads (perpendicular to the shaft) and axial loads (parallel to the shaft) in both directions.

High-Speed Capability: Designed for efficiency, deep groove ball bearings operate at high speeds with minimal friction and noise.

Versatility: They are suitable for various applications requiring smooth, reliable rotation under different conditions. - Features:

Seals and Shields: Bearings can be equipped with seals or shields to protect against contaminants and retain lubrication within the bearing. - Quality Assurance:

We ensure quality through stringent processes, including material selection, precision machining, heat treatment for durability, and comprehensive testing.

Quality control measures verify dimensional accuracy, surface finish, and performance characteristics to meet industry standards and customer requirements.

These bearings are prized for their high-speed operation, quiet performance, and ability to function reliably in a variety of applications, including industrial machinery, automotive systems, and household devices.

Tips for Installing Deep Groove Ball Bearings

- Preparation:Ensure the workspace is clean and free of contaminants. Gather all necessary tools and equipment, such as bearing pullers, presses, and clean gloves.

- Inspection:Check the bearing and its housing for any signs of damage or defects before installation. Ensure that the shaft and housing are clean and free of burrs or sharp edges.

- Correct Handling:Handle the bearing with clean, dry hands or gloves to prevent contamination. Avoid dropping or striking the bearing, which can cause damage.

- Proper Alignment:Ensure the bearing is aligned correctly with the shaft and housing. Use alignment tools if necessary to avoid misalignment, which can lead to premature failure.

- Application of Force:Apply force only to the ring that is being press-fitted. For example, apply force to the outer ring when fitting into the housing and to the inner ring when fitting onto the shaft. Use a press or bearing installation tool to apply even pressure. Avoid using a hammer or other impact tools, as they can cause damage.

- Lubrication:Lubricate the bearing with the appropriate type and amount of lubricant specified by the manufacturer. If the bearing is pre-lubricated and sealed, no additional lubrication is necessary.

- Heating and Cooling:For a tight fit, you may need to heat the bearing or cool the shaft. Use an induction heater or an appropriate method to avoid overheating or uneven heating. Do not exceed the temperature limits specified by the manufacturer.

- Seals and Shields:Ensure that any seals or shields are intact and properly positioned. Seals and shields protect the bearing from contaminants and retain lubrication.

- Testing:After installation, rotate the bearing by hand to ensure smooth and free movement. Check for any unusual noise, binding, or resistance.

By following these tips, you can ensure a proper and efficient installation of deep groove ball bearings, leading to enhanced performance and longevity of your equipment.