Uitgebreid Overzicht van de Lagers van de het Typewaterpomp van de Balrol

Bouw

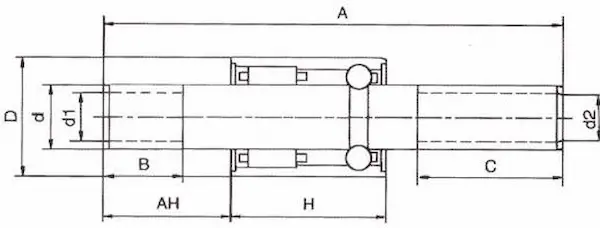

Buitenringen en as: Het kogellager van het type waterpomp heeft een buitenring en as van hoogwaardig staal of een legering. Deze constructie biedt de nodige sterkte en duurzaamheid om de draaibeweging van de waterpompas effectief te ondersteunen. De as is voorzien van groeven die ontworpen zijn om de rollen en kogels op te nemen, wat een soepele en efficiënte werking mogelijk maakt.

Rol- en kogelelementen: Dit lagertype onderscheidt zich van traditionele kogellagers door cilindrische of conische rollen in plaats van sferische kogels. Deze rollen bieden een groter contactoppervlak met de binnenste en buitenste loopbanen in vergelijking met kogellagers. Dit grotere oppervlak verbetert de belastbaarheid en duurzaamheid van het lager, waardoor het geschikt is voor toepassingen die robuuste prestaties vereisen onder verschillende omstandigheden.

Afdichtingsmechanismen: De kogellager is uitgerust met geavanceerde afdichtingsmechanismen, waaronder afdichtingen of schilden, die ontworpen zijn om te beschermen tegen verontreinigingen zoals water, stof en vuil. Deze bescherming is cruciaal voor het behoud van de levensduur en prestaties van het lager, vooral in ruwe bedrijfsomgevingen waar blootstelling aan externe elementen een probleem is.

Prestaties en toepassingen

Laadvermogen: Dankzij hun robuuste ontwerp kunnen kogellagers zwaardere belastingen en hogere snelheden aan in vergelijking met conventionele kogellagers. Hierdoor zijn ze ideaal voor gebruik in waterpompen voor auto's en industriële pompsystemen, waar betrouwbare prestaties onder wisselende omstandigheden van cruciaal belang zijn. Hun vermogen om aanzienlijke belastingen te verwerken en stress te weerstaan draagt bij tot hun doeltreffendheid in veeleisende toepassingen.

Warmteafvoer: Een van de voordelen van een kogellager is de efficiënte warmteafvoer. Het grotere contactoppervlak tussen de rollen en loopbanen zorgt voor een betere warmtehuishouding, wat de bedrijfszekerheid van het lager verhoogt en de levensduur verlengt. Dit is vooral belangrijk in toepassingen waar warmteontwikkeling de prestaties en levensduur kan beïnvloeden.

Veelzijdigheid: Kogelrollagers zijn veelzijdige onderdelen die geschikt zijn voor een breed scala aan waterpomptoepassingen. Ze worden vaak gebruikt in koelsystemen voor auto's, agrarische irrigatiesystemen, HVAC-eenheden en diverse industriële processen. Door hun betrouwbare prestaties zijn ze de keuze bij uitstek in situaties waar een consistente werking essentieel is.

Kwaliteit

Materialen en productie: Onze kogellagers worden vervaardigd met behulp van geavanceerde productietechnieken en voldoen aan strenge normen voor kwaliteitscontrole. Er worden hoogwaardige materialen geselecteerd om duurzaamheid en betrouwbaarheid te garanderen. Het nauwgezette assemblageproces zorgt ervoor dat elk lager voldoet aan de vereiste precisie- en prestatiecriteria.

Testen en certificering: Elk lager wordt onderworpen aan strenge tests om de nauwkeurigheid van de afmetingen, het draagvermogen en de weerstand tegen omgevingsfactoren te verifiëren. Deze tests zorgen ervoor dat de lagers voldoen aan de industrienormen en aan de specificaties van de klant. Certificeringsprocessen valideren verder de kwaliteit en betrouwbaarheid van de lagers.

Tips voor optimale prestaties

Juiste installatie: Gebruik het juiste gereedschap en de juiste installatietechnieken om ervoor te zorgen dat het lager correct werkt. Houd je aan de specificaties van de fabrikant voor torsie en uitlijning om schade te voorkomen. Vermijd overmatige kracht tijdens de installatie omdat dit het lager of de onderdelen ervan kan beschadigen.

Regelmatig smeren: Volg de aanbevelingen van de fabrikant met betrekking tot het type en de hoeveelheid te gebruiken smeermiddel. Controleer het smeermiddel regelmatig en vul het bij om optimale prestaties van de lagers te behouden. Zorg ervoor dat het smeermiddel schoon en vrij van verontreinigingen is om problemen te voorkomen.

Juiste pasvorm en uitlijning: Controleer of het lager goed in zijn behuizing en op de as past om uitlijnfouten te voorkomen. Controleer regelmatig op tekenen van verkeerde uitlijning, die kunnen leiden tot ongelijkmatige slijtage en voortijdige uitval. Gebruik precisiegereedschap om de uitlijning te meten en indien nodig aan te passen.

Juiste behandeling: Behandel lagers voorzichtig tijdens transport en installatie om fysieke schade te voorkomen. Gebruik schone handschoenen om vervuiling door olie en vuil te voorkomen. Laat het lager niet vallen of sla er niet tegenaan, want dergelijke schokken kunnen deuken veroorzaken en de prestaties beïnvloeden.

Belastingbeheer: Zorg ervoor dat het lager niet wordt blootgesteld aan belastingen die de nominale capaciteit overschrijden. Vermijd schokbelastingen of plotselinge schokken die het lager kunnen beschadigen. Verdeel ladingen gelijkmatig om gelokaliseerde spanning op de lageronderdelen te voorkomen.

Conclusie

Het kogellager van het type waterpomp blinkt uit in robuuste prestaties en betrouwbaarheid in veeleisende operationele omgevingen. De superieure belastbaarheid, efficiënte warmteafvoer en effectieve afdichtingsmechanismen maken het een ideale keuze voor kritieke toepassingen waar betrouwbare prestaties essentieel zijn. Door de juiste onderhouds- en hanteringspraktijken te volgen, kun je de levensduur en efficiëntie van je waterpomplagers maximaliseren, zodat je machines soepel en betrouwbaar werken.