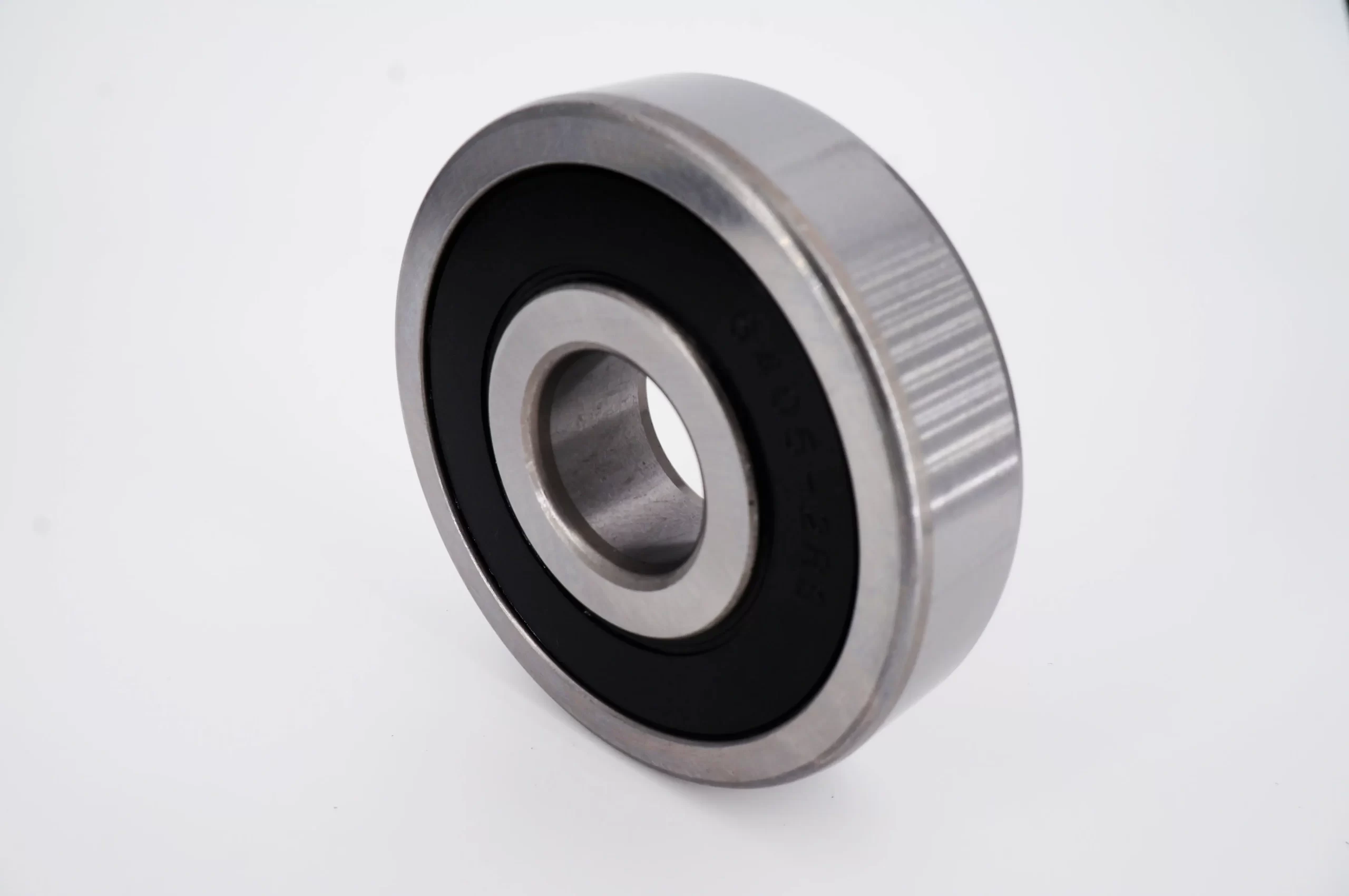

高性能深溝玉軸受:汎用性と信頼性

深溝玉軸受は、その適応性と信頼性から、様々な産業で極めて重要な役割を果たしています。ラジアル荷重とアキシャル荷重の両方に対応できる深溝玉軸受は、さまざまな用途で欠かせない存在です。ここでは、深溝玉軸受の機能性と、最高の性能を保証するための当社の包括的な品質管理手順の概要を説明します。

アプリケーション

電動モーター当社の深溝玉軸受は、電動モーターの基本であり、高速回転とラジアル応力に対応します。効率と耐久性を両立させた設計で、家電製品から産業機械まで幅広く使用されています。

自動車分野:これらのベアリングは、ホイール、トランスミッション、ディファレンシャルなど、多くの自動車部品に不可欠です。これらのベアリングは、自動車の円滑な運転を促進し、効率性と信頼性の両方を向上させます。高荷重に対応し、様々な速度に適応する能力は、最適な車両性能を実現する上で極めて重要です。

家庭用電化製品:洗濯機、掃除機、扇風機などの日常的な機器は、静かで信頼性の高い動作のために当社のベアリングに依存しています。低摩擦と長持ちする耐久性により、これらの家電製品が効率的に動作し、長持ちすることを保証します。

産業機器:深溝玉軸受は、コンベヤ、ポンプ、ギヤボックスなどの機械に使用されています。深溝玉軸受の堅牢な設計は、大きな荷重を支え、摩擦を最小限に抑え、効果的で信頼性の高い機械性能を保証します。

品質管理プロセス

深溝玉軸受の高い性能と耐久性を保証するため、厳格な品質管理体制を敷いています:

1.材料検査:

原材料原材料の化学的および機械的試験を総合的に実施し、ベアリング製造に適していることを確認しています。

トレーサビリティ:詳細なバッチ記録により、材料の起源を追跡し、一貫した品質を維持することができます。

2.精密製造:

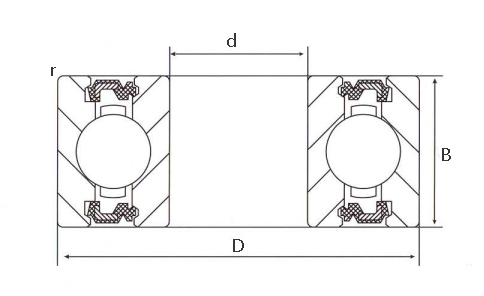

寸法精度:当社の精密機械加工と定期的な機器校正により、ベアリングは厳格な公差基準を満たしています。

表面仕上げ:摩擦を減らし、性能を向上させる滑らかな表面を実現するために、高度な仕上げ技術が採用されている。

3.熱処理:

制御された処理:当社の熱処理手順は、望ましい硬度と強度を達成するために慎重に制御されています。

硬度試験:ベアリングは、指定された要件を満たしていることを確認するために、処理後に厳格な硬度試験を受けます。

4.組み立てと潤滑:

清潔な組み立て:ベアリングは、清潔な工具と手袋を使用し、汚染のない環境で組み立てられる。

潤滑:ベアリングのライフサイクルを通じて安定した性能を確保するため、適切な潤滑剤を適切な量だけ塗布します。

5.試験と検査:

寸法チェック精密機器を使用してベアリングの寸法を測定し、確認します。

荷重と速度の評価:軸受は模擬条件下で試験され、指定された荷重と速度での性能を確認する。

騒音・振動分析:専門機器を用いて異常な騒音や振動を検出し、高品質を保証します。

非破壊検査:超音波検査や磁粉探傷検査などの技術は、ベアリングを傷つけることなく内部の欠陥を特定するために使用されます。

6.シーリングとシールド:

シールの完全性シールとシールドが適切に設置され、有効であることを確認するために、リークテストを実施します。

材料試験:シール材は、運転条件や潤滑油との適合性を試験される。

7.品質保証への取り組み:

統計的工程管理(SPC):SPCの手法は、生産工程を監視・管理し、一貫した品質を確保するために採用される。

ISO認証取得:ISO 9001などの国際規格に準拠し、定期的な監査を実施し、高品質を維持しています。

継続的改善:私たちは、製品の品質と業務効率を高めるため、継続的な改善に取り組んでいます。

8.梱包と取り扱い:

安全な梱包:ベアリングは、汚染や損傷を防ぐために保護材で慎重に梱包されています。

取り扱い手順:当社のスタッフは、輸送中および設置中にベアリングを正しく取り扱い、損傷を避けるためのトレーニングを受けています。

9.カスタマーサポート:

フィードバックの収集:私たちは、お客様の声を積極的に収集・分析し、問題に対処し、製品の改善を推進しています。

技術支援:当社のチームは、ベアリングの最適な性能を確保するために、正しい使用方法、設置方法、およびメンテナンスに関するガイダンスを提供します。

深溝玉軸受6400の最適な性能と寿命を確保するには、適切なメンテナンスと取り付け方法を守ることが重要です。まず、取り付けから始めましょう。正しい工具を使用し、ベアリングの損傷を避けるために、トルクとアライメントに関するメーカーの仕様を守ることが不可欠です。取り付け時に過度の力が加わると、ベアリングの完全性が損なわれる可能性があるため、推奨される手順に従って適切に取り付けることが重要です。

定期的な潤滑も重要な点です。常にメーカーが指定した種類と量の潤滑剤を使用してください。潤滑剤を定期的にチェックし、補充することは、ベアリングの最適な性能を維持するのに役立ちます。さらに、潤滑剤を清潔に保ち、汚染物質を含まないようにすることは、ベアリングの損傷を防ぐために不可欠です。汚染された潤滑油は、早期摩耗や故障につながる可能性があります。

正しいはめあいおよびアライメントは、ベアリングの性能に重要な役割を果たします。ベアリングの寿命にとって重要なミスアライメントを防ぐために、ベアリングがハウジング内とシャフト上に正しくフィットしていることを確認します。精密工具を使用して定期的にアライメントをチェックすることで、偏摩耗や早期故障を防ぐことができます。適切なアライメントを確保するために必要な調整を行うことは、ベアリングのスムーズな動作と耐久性に貢献します。

ベアリングの適切な取り扱いも重要です。取り扱いには十分注意し、輸送中や設置中の物理的な損傷を避けてください。手の油や汚れによる汚染を防ぐため、清潔な手袋を使用してください。ベアリングを落としたり、ぶつけたりすることは、へこみの原因となり、性能に影響を与えます。

荷重を効果的に管理することが、ベアリングの性能を維持する鍵です。軸受に定格以上の荷重がかからないようにすることで、過負荷を避けることができます。過大な荷重は破損の原因となり、ベアリングの寿命を縮めます。荷重を均等に分散させることで、軸受部品に局所的な応力がかかるのを防ぎ、軸受の性能と寿命に貢献します。

これらのガイドラインに従うことで、深溝玉軸受6400は卓越した信頼性と性能を発揮します。定期的なメンテナンスと慎重な取り扱いは、一般的な問題を未然に防ぎ、様々な用途でのスムーズで長持ちする運転を保証するために不可欠です。これらのことを実践することで、ベアリングの性能を向上させ、耐用年数を延ばすことができ、さまざまな使用環境の要求に確実に応えることができます。

Vankv Wuxi Machinery Equipment Co., Ltd.では、様々な用途で優れた信頼性と性能を提供する深溝玉軸受の製造に特化しています。2014年以来、高品質のベアリングの輸出に専念しており、お客様のニーズをサポートします。

ご質問や詳細については、お気軽にお問い合わせください。