Bantalan Pompa Air (Tipe Bola-Bola): Konstruksi, Fungsionalitas, Aplikasi, dan Jaminan Kualitas

Bantalan Pompa Air Tipe Bola-Bola direkayasa untuk keunggulan dalam aplikasi pompa air otomotif dan industri. Desainnya yang kuat dan kinerja tinggi menjadikannya komponen penting dalam berbagai sistem penting.

Desain dan Konstruksi

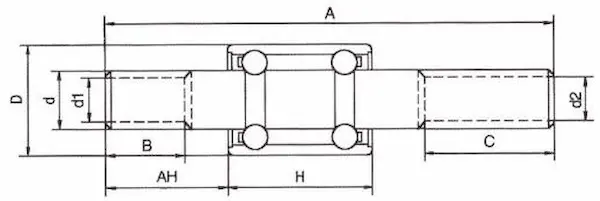

Bantalan Pompa Air Tipe Bola-Bola dibuat dengan cermat untuk memastikan daya tahan dan efisiensi yang optimal. Bantalan ini memiliki cincin luar yang kokoh yang melekat kuat pada poros pompa air, memberikan stabilitas selama pengoperasian. Secara internal, mereka menggunakan konfigurasi dua baris bola baja, yang diberi jarak yang tepat dan dipisahkan oleh sangkar untuk memfasilitasi gerakan yang mulus dan mengurangi gesekan. Pengaturan ini sangat penting untuk menangani beban radial dan aksial yang besar.

Bantalan juga dapat mencakup segel atau perisai, tergantung pada aplikasinya. Elemen pelindung ini sangat penting untuk mencegah masuknya kontaminan seperti air, kotoran, dan serpihan, sekaligus mempertahankan pelumasan yang penting.

Fungsionalitas dan Kinerja

Bantalan Pompa Air Tipe Bola-Bola dirancang untuk menawarkan kinerja yang andal dan efisien di berbagai kondisi pengoperasian. Susunan bola dua barisnya meningkatkan kapasitas pengangkutan beban bantalan, mengelola tekanan radial dan aksial yang biasa ditemui dalam sistem pompa air. Bantalan bekerja secara efisien pada berbagai kecepatan, dengan desainnya yang meminimalkan gesekan dan pembentukan panas untuk memastikan pengoperasian yang lancar bahkan di bawah kecepatan rotasi tinggi.

Kehadiran seal atau perisai merupakan bagian integral dari fungsinya, memperpanjang masa pakai bearing dengan melindunginya dari elemen eksternal dan mempertahankan kinerjanya di lingkungan yang menantang.

Aplikasi

Bantalan ini digunakan dalam beberapa aplikasi penting:

- Industri Otomotif: Pada kendaraan, Bantalan Pompa Air Tipe Bola-Bola sangat penting untuk mengedarkan cairan pendingin melalui mesin, membantu mencegah panas berlebih dan memastikan kinerja mesin yang optimal. Keandalannya sangat penting untuk mempertahankan suhu pengoperasian yang tepat.

- Pengaturan Industri: Di lingkungan industri, bantalan ini digunakan dalam pompa air untuk tugas-tugas seperti irigasi pertanian, sistem HVAC, dan berbagai industri proses. Mereka sangat penting untuk mempertahankan operasi yang berkelanjutan dan efisien di seluruh aplikasi ini.

Jaminan Kualitas dan Daya Tahan

Memastikan kualitas dan umur panjang Bantalan Pompa Air Jenis Bola-Bola melibatkan proses kontrol kualitas yang ketat. Bantalan dibuat dari baja bermutu tinggi atau baja tahan karat, dipilih karena ketahanannya terhadap korosi dan keausan dalam kondisi yang keras. Teknik pemesinan tingkat lanjut digunakan untuk mencapai dimensi yang tepat dan toleransi yang ketat, dengan proses otomatis dan kontrol kualitas yang ketat untuk memastikan konsistensi.

Setiap bearing menjalani pengujian komprehensif, termasuk pemeriksaan akurasi dimensi, uji kapasitas beban, evaluasi kecepatan rotasi, dan simulasi ketahanan untuk memverifikasi keandalan jangka panjang. Proses produksi kami sesuai dengan standar internasional seperti ISO 9001, dan kami melakukan audit rutin untuk mempertahankan standar kualitas tinggi. Peningkatan berkelanjutan didorong oleh umpan balik pelanggan, meningkatkan teknologi dan kinerja.

Pemeliharaan dan Penanganan

Untuk mengoptimalkan kinerja dan masa pakai Bantalan Pompa Air Tipe Bola-Bola, patuhi panduan berikut:

- Instalasi: Gunakan alat yang tepat dan ikuti spesifikasi pabrikan untuk torsi dan penyelarasan untuk menghindari kerusakan. Hindari tenaga yang berlebihan selama pemasangan.

- Pelumasan: Gunakan jenis dan jumlah pelumas yang direkomendasikan. Periksa dan isi ulang pelumasan secara teratur, pastikan pelumasan tetap bersih untuk mencegah kerusakan bearing.

- Kesesuaian dan Keselarasan: Pastikan bahwa bantalan terpasang dengan benar dan gunakan alat presisi untuk menyesuaikan keselarasan seperlunya.

- Penanganan: Tangani bantalan dengan hati-hati untuk menghindari kerusakan fisik dan kontaminasi. Cegah menjatuhkan atau menghantam bantalan.

- Perlindungan Lingkungan: Gunakan segel dan pelindung untuk melindungi dari kontaminan. Simpanlah bearing di tempat yang bersih dan kering.

- Inspeksi: Periksa bearing secara teratur untuk mengetahui keausan, kerusakan, atau masalah lainnya. Ganti bearing yang menunjukkan tanda-tanda kerusakan untuk mencegah kegagalan.

- Kontrol Suhu: Pantau suhu pengoperasian dan sediakan ventilasi dan pendinginan yang memadai untuk menghindari panas berlebih.

- Manajemen Beban: Pastikan bantalan tidak melebihi kapasitas beban terukur dan hindari benturan mendadak yang dapat menyebabkan kerusakan.

Dengan mengikuti praktik-praktik ini, Anda memastikan bahwa Bantalan Pompa Air Tipe Bola-Bola memberikan kinerja dan daya tahan yang andal, baik dalam aplikasi otomotif atau industri.