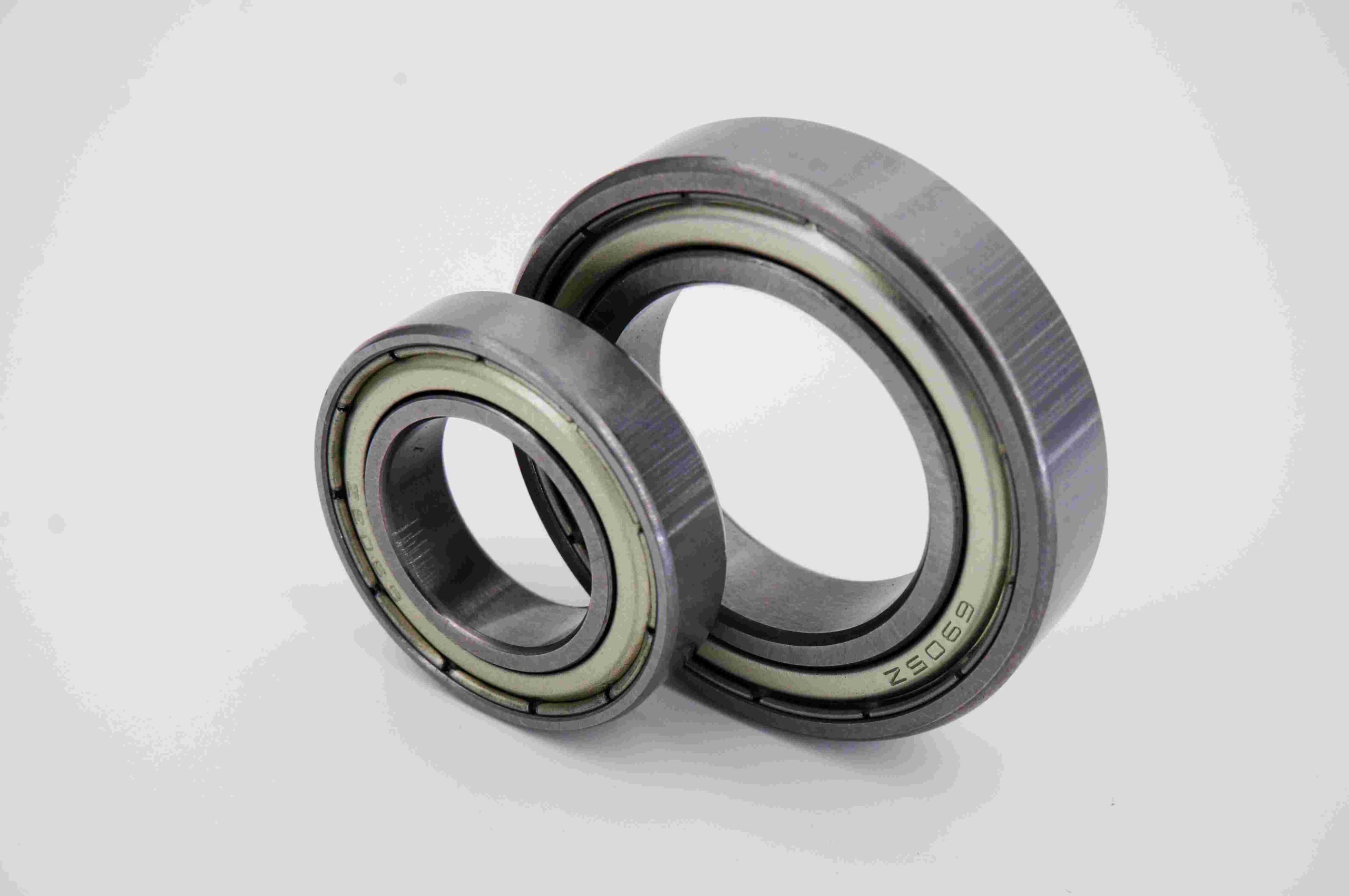

Dalam bidang mesin otomotif dan industri, pengoperasian mesin yang lancar dan efisien, sistem yang digerakkan oleh sabuk, dan berbagai rakitan mekanis merupakan hal yang terpenting. Inti dari sistem ini adalah komponen yang dikenal sebagai bantalan penegang dan pemalas. Bantalan ini, meskipun sering diabaikan, memainkan peran penting dalam memastikan berfungsinya sistem yang digerakkan oleh sabuk dengan mempertahankan tegangan yang benar, memandu sabuk, dan mengurangi gesekan. Artikel ini membahas keuntungan dari tensioner dan idler bearing, menyoroti pentingnya mereka dalam meningkatkan keandalan, kinerja, dan umur panjang alat berat.

1. Memastikan Ketegangan Sabuk yang Optimal

Salah satu fungsi utama dari tensioner dan idler bearing adalah untuk mempertahankan tegangan yang benar dalam sistem yang digerakkan oleh sabuk. Belt, baik pada mesin otomotif maupun mesin industri, bertanggung jawab untuk mentransmisikan daya di antara berbagai komponen, seperti poros engkol, alternator, dan kompresor AC. Namun, seiring berjalannya waktu, belt dapat meregang karena keausan, fluktuasi suhu, dan variasi beban. Peregangan ini dapat menyebabkan hilangnya tegangan, mengakibatkan selip, berkurangnya efisiensi, dan bahkan kegagalan belt.

Bantalan tensioner dirancang untuk secara otomatis menyesuaikan dan mempertahankan tegangan optimal pada sabuk, mengimbangi setiap peregangan yang terjadi. Fitur yang dapat menyesuaikan sendiri ini memastikan bahwa sabuk tetap kencang dan sejajar, mencegah selip dan memastikan transmisi daya yang efisien. Dengan mempertahankan tegangan yang benar, bantalan tensioner membantu mengurangi keausan pada sabuk dan komponen lainnya, memperpanjang masa pakainya dan meminimalkan kebutuhan akan perawatan yang sering.

2. Mengurangi Gesekan dan Keausan

Kedua bantalan tensioner sangat penting dalam mengurangi gesekan di dalam sistem yang digerakkan oleh sabuk. Gesekan merupakan faktor penting dalam keausan komponen mekanis. Dalam sistem yang digerakkan oleh sabuk, gesekan antara sabuk dan katrol dapat menyebabkan panas berlebih, peningkatan konsumsi energi, dan keausan dini pada sabuk dan katrol.

Bantalan pemalas, yang dipasang pada katrol pemalas, berfungsi sebagai pemandu untuk sabuk, memastikan sabuk mengikuti jalur yang benar dan mempertahankan kontak dengan drive dan katrol yang digerakkan. Bantalan ini dirancang untuk meminimalkan gesekan dengan menyediakan permukaan yang halus dan rendah hambatan untuk dilalui belt. Pengurangan gesekan ini tidak hanya meningkatkan efisiensi sistem tetapi juga mengurangi pembentukan panas, yang dapat merusak sabuk dan komponen di sekitarnya.

Bantalan penegang, dengan mempertahankan tegangan yang tepat, juga berkontribusi untuk mengurangi gesekan. Belt yang dikencangkan dengan benar akan berjalan dengan lancar dan konsisten, meminimalkan jumlah gaya kontak antara belt dan katrol. Hal ini mengurangi gesekan keseluruhan dalam sistem, sehingga mengurangi keausan pada komponen, umur belt yang lebih lama, dan meningkatkan kinerja secara keseluruhan.

3. Meningkatkan Keandalan Sistem

Keandalan adalah faktor penting dalam sistem mekanis apa pun, baik dalam mobil, mesin industri, atau alat berat. Kegagalan satu komponen dapat menyebabkan waktu henti yang mahal, perbaikan yang mahal, dan, dalam beberapa kasus, kerusakan besar pada seluruh sistem. Bantalan penegang dan pemalas memainkan peran penting dalam meningkatkan keandalan sistem yang digerakkan oleh sabuk.

Dengan mempertahankan tegangan yang tepat dan mengurangi gesekan, bantalan ini membantu mencegah selip sabuk, ketidaksejajaran, dan keausan dini. Hal ini memastikan bahwa sistem yang digerakkan oleh sabuk beroperasi dengan lancar dan efisien, sehingga mengurangi kemungkinan kegagalan yang tidak terduga. Selain itu, bantalan tensioner dan idler biasanya dirancang untuk tahan terhadap kondisi pengoperasian yang keras, seperti suhu tinggi, beban berat, dan paparan kontaminan seperti debu dan kelembapan. Daya tahan dan ketahanannya terhadap keausan menjadikannya pilihan yang andal untuk berbagai aplikasi, mulai dari mesin otomotif hingga sistem konveyor industri.

Selain mencegah kerusakan belt, tensioner dan idler bearing juga berkontribusi terhadap umur panjang komponen lain dalam sistem. Sebagai contoh, pada mesin otomotif, bantalan tensioner yang berfungsi dengan baik memastikan bahwa timing belt atau serpentine belt tetap sejajar dan dikencangkan dengan benar, sehingga mencegah keausan yang berlebihan pada katrol, alternator, pompa air, dan aksesori lainnya. Hal ini tidak hanya memperpanjang usia komponen-komponen ini, tetapi juga mengurangi risiko perbaikan dan perawatan yang mahal.

4. Meningkatkan Efisiensi dan Kinerja

Efisiensi adalah pertimbangan utama dalam sistem mekanis apa pun, terutama di industri di mana konsumsi energi dan biaya operasional merupakan faktor penting. Tensioner dan bantalan pemalas berkontribusi pada peningkatan efisiensi dan kinerja dalam beberapa cara.

Pertama, dengan mempertahankan ketegangan sabuk yang optimal, bantalan tensioner memastikan bahwa sistem yang digerakkan oleh sabuk beroperasi pada efisiensi puncak. Sabuk yang dikencangkan dengan benar mentransmisikan daya secara lebih efektif, mengurangi kehilangan energi karena selip atau ketidaksejajaran. Hal ini mengarah pada peningkatan efisiensi bahan bakar dalam aplikasi otomotif dan mengurangi konsumsi energi dalam pengaturan industri.

Kedua, pengurangan gesekan yang dicapai oleh tensioner dan bantalan pemalas meningkatkan kinerja sistem secara keseluruhan. Dengan lebih sedikit gesekan, sistem membutuhkan lebih sedikit daya untuk beroperasi, menghasilkan operasi yang lebih halus dan mengurangi ketegangan pada mesin atau motor. Hal ini dapat menghasilkan akselerasi yang lebih baik, respons yang lebih baik, dan pengoperasian yang lebih tenang dalam aplikasi otomotif, sementara dalam pengaturan industri, hal ini dapat menghasilkan produktivitas yang lebih tinggi dan biaya operasional yang lebih rendah.

Terakhir, bantalan tensioner dan idler berkontribusi pada kinerja yang lebih konsisten dan andal dari waktu ke waktu. Dengan mencegah masalah seperti selip sabuk dan ketidaksejajaran, bantalan ini membantu menjaga fungsi sistem yang optimal, memastikan bahwa sistem beroperasi pada kondisi terbaiknya selama masa pakainya. Konsistensi dalam kinerja ini sangat penting dalam aplikasi di mana presisi dan keandalan sangat penting, seperti dalam proses manufaktur atau mesin berkinerja tinggi.

5. Menyederhanakan Pemeliharaan dan Mengurangi Waktu Henti

Perawatan adalah bagian yang tak terhindarkan dari pengoperasian sistem mekanis apa pun, tetapi meminimalkan frekuensi dan kompleksitas tugas perawatan dapat secara signifikan mengurangi waktu henti dan biaya terkait. Tensioner dan bantalan pemalas dirancang untuk menyederhanakan perawatan dan memperpanjang interval antara servis.

Salah satu keuntungan utama dari bantalan tensioner adalah kemampuannya untuk secara otomatis menyesuaikan ketegangan sabuk sesuai kebutuhan. Fitur yang dapat menyesuaikan sendiri ini menghilangkan kebutuhan untuk penyesuaian ketegangan manual, mengurangi waktu dan upaya yang diperlukan untuk pemeliharaan. Dalam banyak kasus, bantalan tensioner dirancang untuk bertahan selama masa pakai belt, yang berarti hanya perlu diperiksa atau diganti ketika belt sudah waktunya diganti.

Idler bearing, meskipun tidak dapat menyesuaikan sendiri, biasanya dirancang untuk masa pakai yang lama dan penggantian yang mudah. Perannya dalam memandu belt dan mengurangi gesekan berarti bahwa mereka mengalami keausan yang relatif rendah dibandingkan dengan komponen lain. Ketika penggantian diperlukan, bantalan idler sering kali mudah diakses dan diganti, sehingga meminimalkan waktu henti dan biaya perawatan.

Selain itu, daya tahan dan keandalan bantalan tensioner dan idler mengurangi kemungkinan kegagalan yang tidak terduga, yang dapat menyebabkan waktu henti yang tidak terencana dan mahal. Dengan memastikan bahwa sistem yang digerakkan oleh sabuk beroperasi dengan lancar dan efisien, bantalan ini berkontribusi pada jadwal perawatan yang lebih dapat diprediksi dan dikelola.

6. Keserbagunaan dan Beragam Aplikasi

Tensioner dan idler bearing adalah komponen yang sangat serbaguna yang digunakan dalam berbagai aplikasi, mulai dari mesin otomotif hingga mesin industri dan lainnya. Kemampuannya untuk mempertahankan tegangan sabuk yang tepat, mengurangi gesekan, dan meningkatkan keandalan membuatnya cocok untuk berbagai jenis sistem yang digerakkan oleh sabuk.

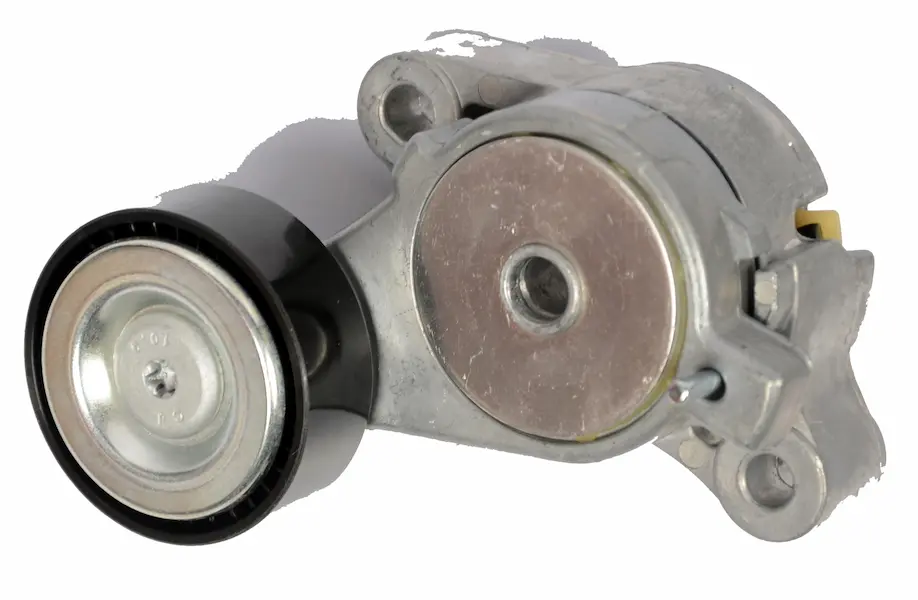

Dalam aplikasi otomotif, bantalan tensioner biasanya digunakan pada sistem serpentine belt, sistem timing belt, dan sistem penggerak aksesori. Sistem-sistem ini memberi daya pada komponen-komponen penting seperti alternator, pompa air, pompa power steering, dan kompresor AC. Keandalan dan efisiensi sistem ini sangat penting untuk kinerja dan keselamatan kendaraan secara keseluruhan.

Dalam pengaturan industri, tensioner dan bantalan pemalas digunakan dalam sistem konveyor, mesin pengemasan, mesin cetak, dan peralatan lain yang mengandalkan mekanisme yang digerakkan oleh sabuk. Kemampuan mereka untuk menahan kondisi operasi yang keras, seperti suhu tinggi, beban berat, dan paparan kontaminan, menjadikannya pilihan ideal untuk aplikasi industri yang menuntut.

Selain itu, bantalan tensioner tersedia dalam berbagai desain dan bahan, sehingga dapat disesuaikan dengan aplikasi tertentu. Misalnya, beberapa bantalan tensioner dilengkapi dengan mekanisme peredam untuk mengurangi getaran, sementara yang lain dirancang dengan bahan tahan suhu tinggi untuk digunakan di lingkungan yang ekstrim. Keserbagunaan ini memastikan bahwa bantalan tensioner dan idler dapat memenuhi persyaratan unik dari berbagai industri dan aplikasi.

Kesimpulan

Bantalan tensioner mungkin merupakan komponen kecil, tetapi dampaknya terhadap kinerja, keandalan, dan efisiensi sistem yang digerakkan oleh sabuk sangat besar. Dengan mempertahankan tegangan sabuk yang tepat, mengurangi gesekan, meningkatkan keandalan, dan menyederhanakan perawatan, bantalan ini memainkan peran penting dalam memastikan kelancaran pengoperasian mesin otomotif, mesin industri, dan sistem mekanis lainnya. Keserbagunaan dan kemampuannya untuk bekerja dalam kondisi yang menantang membuatnya sangat diperlukan dalam berbagai aplikasi. Karena teknologi terus berkembang, tensioner dan idler bearing akan tetap menjadi komponen penting, berkontribusi pada kemajuan dan kesuksesan yang berkelanjutan dari berbagai industri.