Engineered Excellence: Meie pingutusmehhanismid ja rihmarattad on täiustatud insener-tehnoloogia ja rangete katsete tulemus, mis tagab, et need vastavad Land Roveri ja Volvo rangetele nõuetele või ületavad neid. Meie tooted, mis on keskendunud täpsusele ja vastupidavusele, tagavad optimaalse jõudluse igas sõidutingimuses.

Vastupidav disain: Meie pingutusmehhanismid ja rihmarattad on ehitatud nii, et need peavad vastu Land Roveri ja Volvo sõidutingimuste nõuetele ning on valmistatud tugeva konstruktsiooni ja kvaliteetsetest materjalidest. Need on konstrueeritud sujuvaks ja usaldusväärseks, säilitades mootori tõhusaks tööks järjepideva rihmapinge ja joonduse.

Tulemuslikkuse suurendamine: Õige rihmapingutus on kriitilise tähtsusega mootori selliste komponentide nagu vahelduvvoolugeneraatorite, veepumpade ja kliimaseadmete kompressorite töö jaoks. Meie tooted on konstrueeritud nii, et need optimeerivad rihma jõudlust, vähendavad kulumist ja suurendavad mootori üldist tõhusust.

Individuaalsed lahendused: Olenemata sellest, kas sõidate karmi Land Rover Defenderiga või keerulise Volvo XC90-ga, meie ulatuslik valik pingutusmehhanisme ja tühikäigurattaid pakub täpset sobivust ja ühilduvust. Pakume lahendusi, mis vastavad teie sõiduki mudeli ja mootoritüübi erivajadustele.

Klientide pühendumine: Vankv on pühendunud klientide rahulolule ja toote tipptasemele. Meie meeskond tagab, et iga pingutus- ja tühikäiguratas läbib põhjalikud kvaliteedikontrolli meetmed, mis tagavad usaldusväärsuse ja jõudluse, mida võite usaldada.

Tutvu meie valikuga: Avastage kogu Land Roveri ja Volvo sõidukite jaoks saadaolevate pingutusmehhanismide ja rihmarataste valik Vankvilt. Tutvuge meie veebikataloogiga või võtke ühendust meie ekspertide meeskonnaga, et saada personaalset abi teie sõidukile sobiva lahenduse valimisel.

Kas olete valmis kogema meie pingutusmehhanismide ja rihmarataste täpsust ja jõudlust? Võtke juba täna ühendust Vankviga, et saada rohkem teavet selle kohta, kuidas meie tooted võivad teie Land Roveri või Volvo sõidukogemust tõsta.

Pingutus- ja rihmarataste hooldusnõuanded

- Regulaarne kontroll:

- Visuaalne kontroll: Kontrollige regulaarselt pingutusrullikut ja tühikäigurattaid kulumise, kahjustuste või valesti paigutatud rihmarataste suhtes.

- Kontrollige rihma seisundit: Kontrollige serpentiin- või ajastusrihma pragude, kulumise või klaasistumise suhtes. Kahjustatud rihm võib mõjutada rihmaratta jõudlust.

- Kuulake ebatavalisi helisid:

- Vingumine või vingumine: Kuulake mootori töötamise ajal ebatavalisi helisid. Vinguvad või kriiksuvad helid võivad viidata kulunud laagritele või valele paigutusele.

- Rääksumine või lihvimine: Need müra viitavad sageli pingutusseadme või tühikäiguketta laagri riketele.

- Rihma pinge testimine:

- Käsitsi kontrollimine: Vajutage rihma alla kahe rihmaratta vahelisel poolel. See peaks veidi järele andma, tavaliselt umbes pool tolli. Liiga suur või liiga väike liikumine võib viidata probleemile.

- Rihma pingutusmõõtur: Täpsema mõõtmise jaoks kasutage rihma pingemõõturit. Järgige tootja spetsifikatsioone õige pinge tagamiseks.

- Kontrollige joondamist:

- Visuaalne joondamine: Veenduge, et rihm jookseb sirgelt ja õigesti üle kõigi rihmarataste. Vale joondus võib põhjustada ebaühtlast kulumist ja enneaegset rikkeid.

- Laserkorrastustööriistad: Kasutage täpsema hinnangu andmiseks laseriga joondamise vahendeid.

- Määrimine:

- Laagertihendid: Kaasaegsetel pingutusmehhanismidel ja tühikäiguratastel on tavaliselt tihendatud laagrid, mis ei vaja määrimist. Kui teie rihmarattad ei ole tihendatud, kasutage regulaarselt sobivat määrdeainet vastavalt tootja soovitustele.

- Vältige liigset määrimist: Liigne määrimine võib ligi tõmmata mustust ja prahti, mis põhjustab kulumist.

- Vahetage kulunud komponendid välja:

- Kulumismärgid: Vahetage pingutusrattad ja tühikäigurattad välja, kui märkate liigset mängimist, krobelist või mürarikast pöörlemist või nähtavaid kahjustusi.

- Tootja soovitused: Järgige nende osade väljavahetamiseks sõiduki tootja hooldusgraafikut, mis on tavaliselt umbes 60 000 kuni 100 000 miili pikkune.

- Korralik puhastamine:

- Prahi eemaldamine: Hoidke mootoriruumi puhtana, et vältida mustuse ja prahi kogunemist rihmaratastele ja rihmale.

- Tavaline pesemine: Vajaduse korral puhastage rihmarattad ümberringi kerge mootoripuhastusvahendiga ja harjaga. Vältige kõrgsurvepesu otse komponentidele.

Miks valida meid?

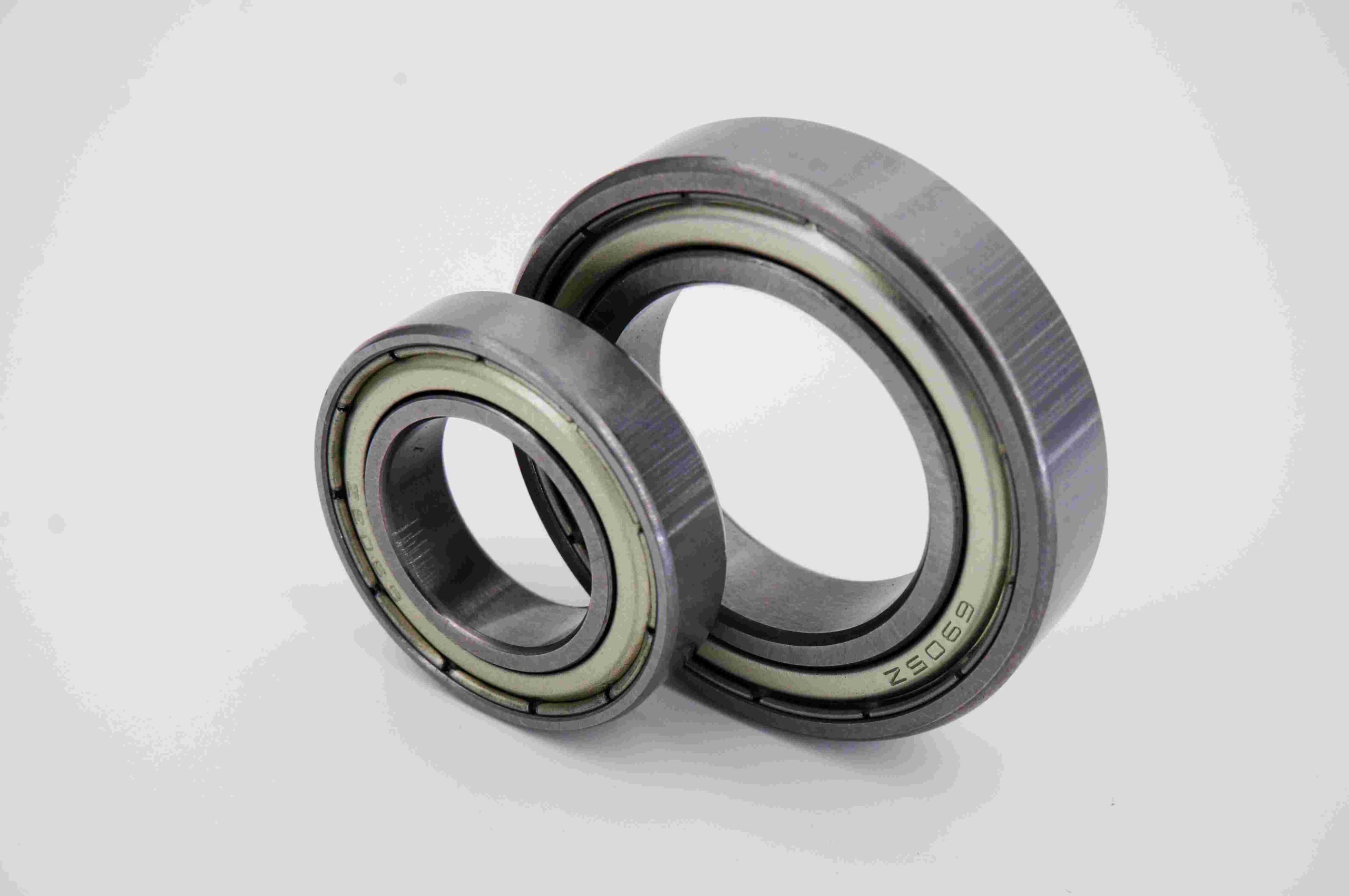

Vankv Wuxi Machanical Equipment Co., Ltd. asutati 2014. aastal kui ettevõte, mis on spetsialiseerunud süvarõngaga kuullaagrite, veepumba laagrite ja rattarummu laagrite tootmisele.

Tänu pidevatele tehnoloogilistele uuendustele ja täiustatud tootmisseadmetele kasutatakse meie laagreid laialdaselt kogu maailmas erinevates tööstusharudes, sealhulgas autotööstuses, elektrimootorites, kodumasinates, kontoriseadmetes, elektrilistes tööriistades jne.

Meie inseneride meeskond töötab iga kuu järjekindlalt välja uusi tooteid, et pakkuda sellele tööstusele kvaliteetseid teenuseid.Ootame innukalt koostööd teiega.

Juhindudes "innovatsiooni" ja "läbimurde" põhifilosoofiast, püüame pidevalt laiendada oma uurimis- ja tootmisvõimsust, et vastata turu nõudmistele, tuues samal ajal järjekindlalt välja täiustatud "Vankv" seeria tooteid.