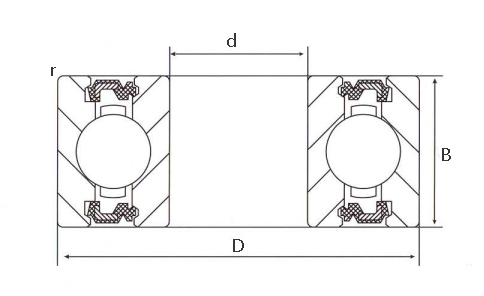

Deep groove ball bearings are a cornerstone in rolling-element bearing technology, renowned for their simple yet highly effective design. They consist of an inner ring, an outer ring, a series of balls, and a cage that separates the balls. The key characteristics of these bearings include their configuration, functionality, protection mechanisms, material composition, and widespread usage.

These bearings are designed with deep grooves in both the inner and outer rings, which allows them to support both axial and radial loads. This design is crucial for applications where forces in both directions are present. Deep groove ball bearings are engineered for high-speed performance and exhibit low friction, enabling them to operate quietly and efficiently. This makes them particularly well-suited for applications requiring smooth and reliable performance under various load conditions.

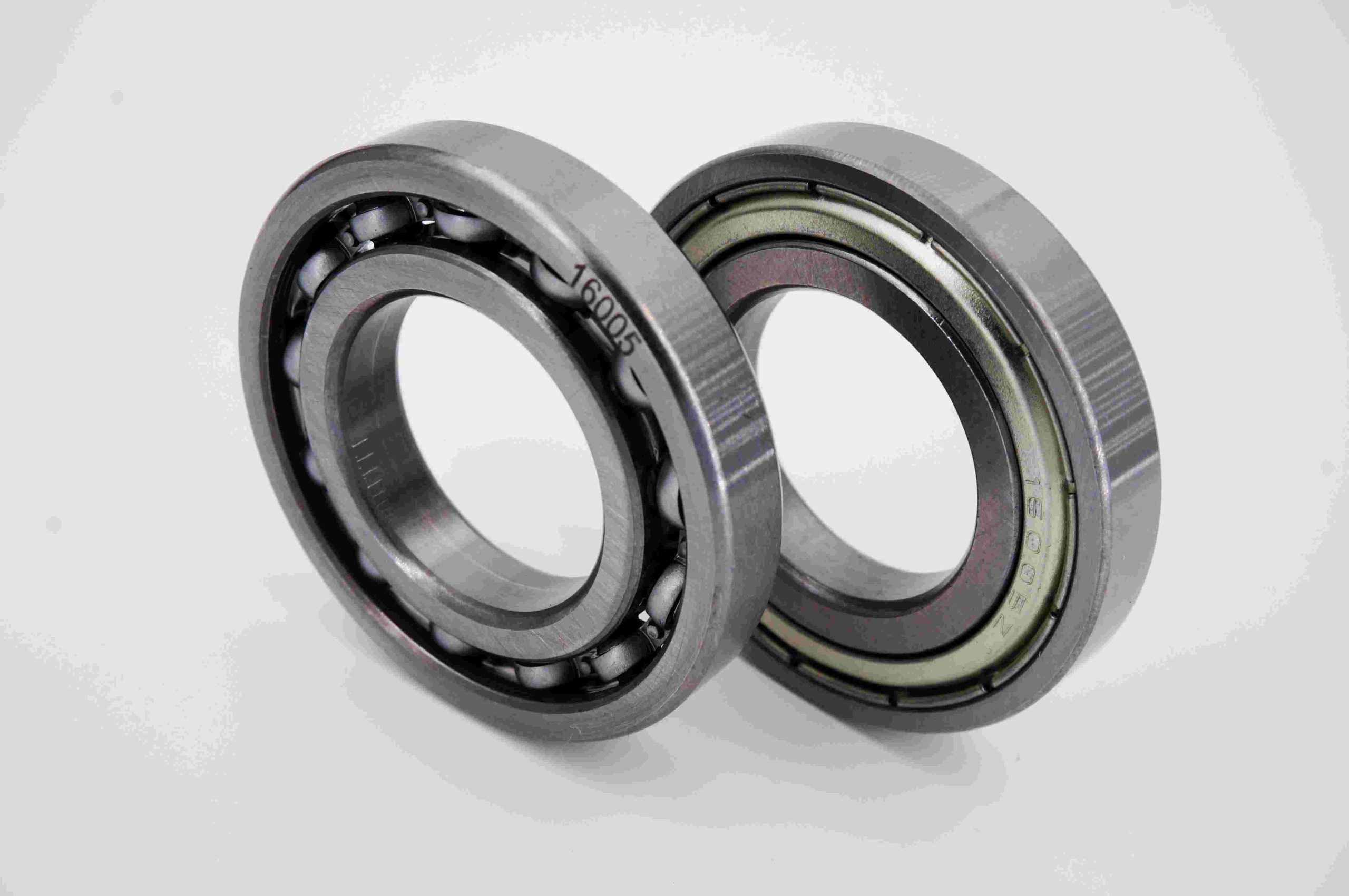

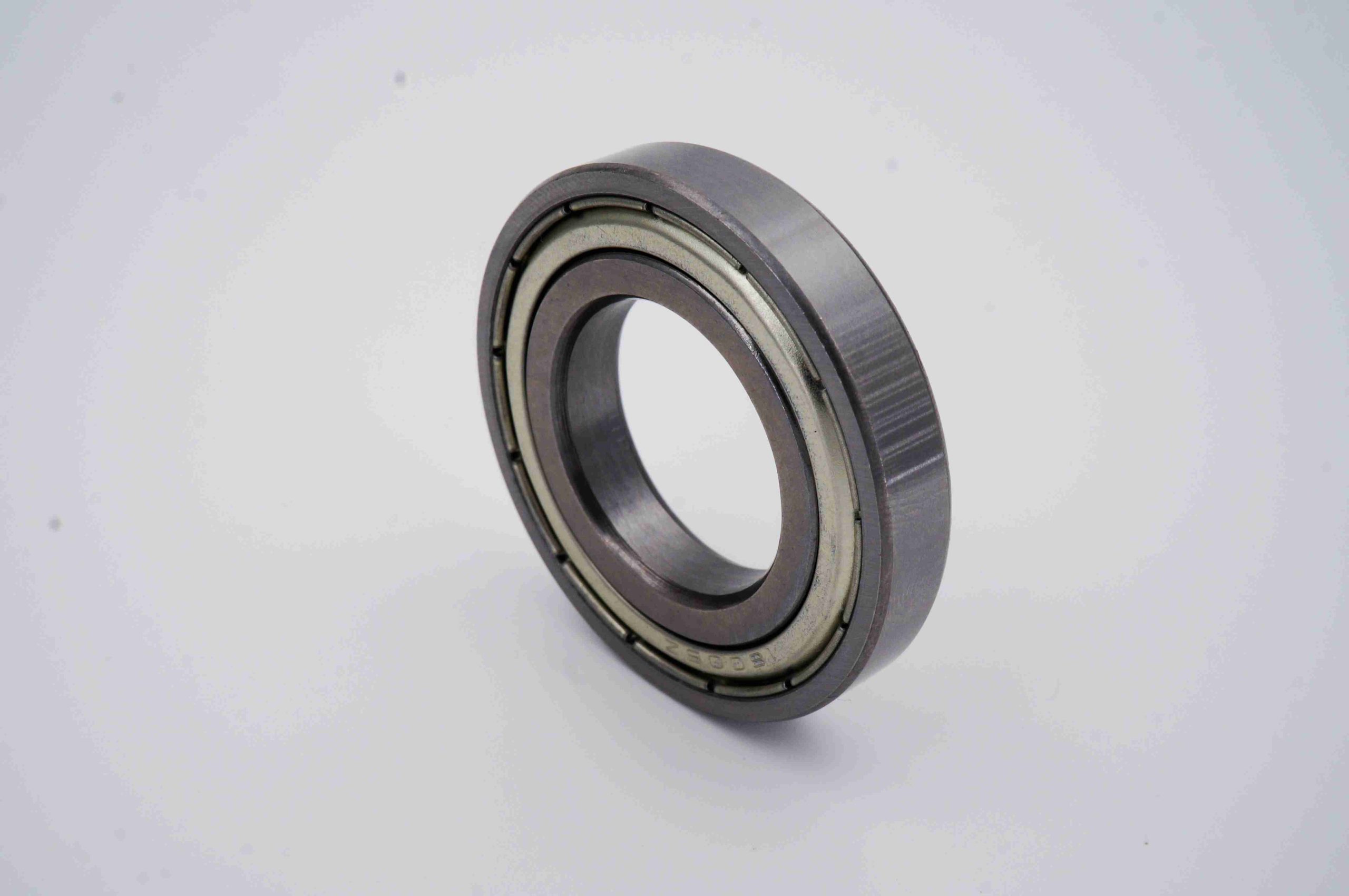

Protection mechanisms are a significant aspect of deep groove ball bearings. They come with different protective features such as seals and shields. Seals provide comprehensive protection against contaminants and help retain lubrication, making them ideal for environments where dust and moisture could be an issue. Shields, on the other hand, offer basic protection against larger particles, helping to extend the lifespan of the bearing.

The material composition of deep groove ball bearings commonly includes high-grade steel, selected based on the performance requirements and size of the bearing. This choice of materials ensures durability and reliability across different applications.

These bearings find applications across numerous sectors including automotive, industrial machinery, and home appliances. Their robustness and dependability make them a preferred choice in various applications such as electric motors, gear systems, and more. Their versatility ensures that they can be used in a wide range of machinery and equipment.

Our bearing factory distinguishes itself through rigorous quality control measures and advanced manufacturing techniques. We emphasize precision engineering and thorough testing procedures to deliver bearings that meet high standards of reliability, efficiency, and longevity.

Material selection and testing are critical aspects of our quality control process. We conduct thorough inspections and tests on raw materials to ensure consistency and quality from the beginning. Advanced manufacturing techniques are employed to guarantee precise dimensions and tolerances. Our automated processes and machinery maintain uniformity across large production batches, reducing the risk of defects.

Comprehensive testing is another cornerstone of our quality assurance. Our multi-stage testing includes assessments of dimensional accuracy, load capacity, and rotational speed. We also perform endurance testing under various operating conditions to ensure the long-term reliability and performance of our bearings. Non-destructive testing methods such as ultrasonic and magnetic particle inspections are used to detect any internal flaws and prevent defects before they impact the final product.

Quality assurance protocols are implemented at every stage of production. We use statistical process control (SPC) to monitor and control the manufacturing process, ensuring that our bearings meet strict quality standards. Adherence to international quality standards, such as ISO 9001, is a testament to our commitment to maintaining high-quality manufacturing practices. Regular audits and reviews ensure ongoing compliance with these standards.

Customer feedback plays a crucial role in our continuous improvement efforts. We actively incorporate feedback into our quality control processes to address any areas for improvement. Our commitment to research, development, and innovation in bearing technology drives us to continuously enhance our products and services.

Over the past few decades, we have built a loyal customer base that values our quality control and after-sales response. We approach every cooperation with dedication and look forward to establishing new partnerships. No matter you have any questions and requirments, please contact us and we will provide our advices. Our goal is to provide top-notch products and services, ensuring that every bearing we produce delivers optimal performance and reliability in various applications.