Οι τεντωτήρες στα αυτοκίνητα είναι κρίσιμα εξαρτήματα που διαδραματίζουν ζωτικό ρόλο στη διατήρηση της αξιοπιστίας, της αποδοτικότητας και της μακροζωίας του συστήματος κίνησης των εξαρτημάτων του κινητήρα.

Εξασφαλίζουν ότι οι ιμάντες ή οι αλυσίδες παραμένουν σωστά τεντωμένες, συμβάλλοντας στην ομαλή και αποδοτική λειτουργία των εξαρτημάτων και των εξαρτημάτων του κινητήρα, ενώ αποτρέπουν πιθανές ζημιές από χαλάρωση ή ολίσθηση.

Οι τροχαλίες των αυτοκινήτων είναι βασικά εξαρτήματα που βοηθούν στην καθοδήγηση και τη διατήρηση της τάσης των ιμάντων κίνησης, εξασφαλίζοντας την ομαλή και αποτελεσματική λειτουργία των εξαρτημάτων του κινητήρα.

Η συντήρηση των τροχαλιών τάνυσης και των τροχαλιών αδρανείας στα αυτοκίνητα είναι απαραίτητη για τη διασφάλιση της ομαλής λειτουργίας του συστήματος κίνησης του ιμάντα, το οποίο με τη σειρά του επηρεάζει την απόδοση διαφόρων εξαρτημάτων του κινητήρα.

Παρέχοντας μια σταθερή πλατφόρμα για την κίνηση του ιμάντα και διατηρώντας τη σωστή τάση, οι τροχαλίες αδράνειας συμβάλλουν στη συνολική αξιοπιστία και απόδοση του κινητήρα και των συστημάτων αξεσουάρ του οχήματος.

Στο πλαίσιο των αυτοκινήτων, ο τεντωτήρας αναφέρεται συγκεκριμένα σε ένα εξάρτημα του συστήματος κίνησης που διατηρεί τη σωστή τάση στους ιμάντες ή τις αλυσίδες.

Η κύρια λειτουργία του είναι να διασφαλίζει ότι αυτοί οι ιμάντες ή αλυσίδες παραμένουν σφιχτοί και σωστά ευθυγραμμισμένοι γύρω από διάφορες τροχαλίες και εξαρτήματα, όπως η γεννήτρια, ο συμπιεστής κλιματισμού, η αντλία νερού, η αντλία υδραυλικού τιμονιού και μερικές φορές οι ιμάντες ή αλυσίδες χρονισμού.

Οι τεντωτήρες αποτρέπουν τη χαλάρωση των ιμάντων ή των αλυσίδων, η οποία είναι ζωτικής σημασίας για την αποτελεσματική λειτουργία και τη μακροζωία των εξαρτημάτων του κινητήρα. Βοηθούν στην αποφυγή της ολίσθησης, η οποία θα μπορούσε να οδηγήσει σε μειωμένη απόδοση ή ακόμη και σε βλάβη του κινητήρα.

Συνήθως αποτελούνται από έναν ελατηριωτό βραχίονα ή μηχανισμό τροχαλίας που εφαρμόζει σταθερή τάση στον ιμάντα ή την αλυσίδα. Αυτό εξασφαλίζει ότι ο ιμάντας παραμένει στη σωστή τάση καθώς φθείρεται με την πάροδο του χρόνου.

Οι τροχαλίες περιστροφής χρησιμοποιούνται για τη δρομολόγηση και τη διατήρηση της τάσης των ιμάντων σερπεντίνης ή των ιμάντων κίνησης στο χώρο του κινητήρα.

Συνήθως είναι τοποθετημένα με τέτοιο τρόπο ώστε να βοηθούν στην αλλαγή της κατεύθυνσης του ιμάντα και στη διατήρηση της κατάλληλης τάσης, διασφαλίζοντας ότι ο ιμάντας δεν θα γλιστρήσει ή δεν θα αποκολληθεί υπό διάφορες συνθήκες λειτουργίας του κινητήρα.

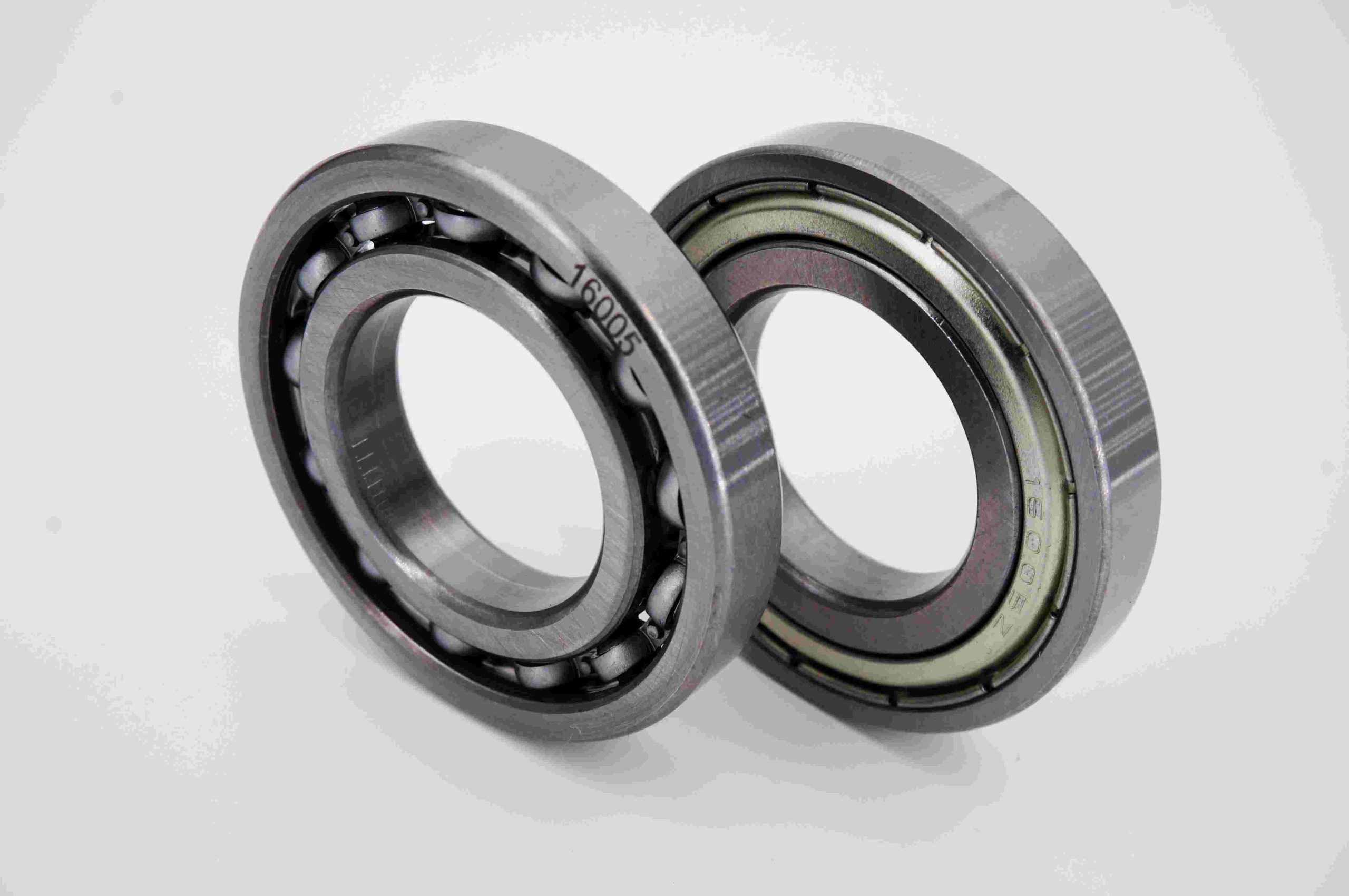

Και είναι συνήθως απλές στη σχεδίαση, αποτελούμενες από ένα σταθερό βραχίονα με έναν λείο ή αυλακωμένο τροχό (τροχαλία) τοποθετημένο σε ρουλεμάν. Ο τροχός της τροχαλίας περιστρέφεται ελεύθερα στο έδρανο, επιτρέποντας στον ιμάντα να κινείται ομαλά γύρω του, διατηρώντας παράλληλα την τάση.

Οι τροχαλίες βρίσκονται συχνά σε περιοχές όπου ο ιμάντας αλλάζει κατεύθυνση ή όπου πρέπει να εφαρμοστεί πρόσθετη τάση για να διατηρηθεί η σωστή ευθυγράμμιση και τάση.

Διαδικασίες ανάπτυξης για τεντωτήρες υψηλής ακρίβειας

- Αρχική ιδέα και σχεδιασμός:

- Ανάλυση απαιτήσεων: Συγκεντρώστε τις ανάγκες των πελατών και τις συνθήκες λειτουργίας.

- Ανάπτυξη ιδεών: Δημιουργία αρχικών σχεδίων με χρήση λογισμικού CAD.

- Μελέτη σκοπιμότητας: Αξιολογήστε την πρακτικότητα, το κόστος και τις δυνατότητες κατασκευής.

- Λεπτομερής μηχανική και προσομοίωση:

- Εκλεπτυσμένος σχεδιασμός: Ανάπτυξη λεπτομερών σχεδίων με ακριβείς διαστάσεις.

- Προσομοίωση: Χρησιμοποιήστε FEA για να ελέγξετε την καταπόνηση και την απόδοση.

- Κινηματική ανάλυση: Εξασφαλίστε την ομαλή κίνηση και αλληλεπίδραση των εξαρτημάτων.

- Επιλογή και δοκιμή υλικών:

- Επιλογή υλικού: Επιλέξτε ανθεκτικά υλικά υψηλής αντοχής.

- Δημιουργία πρωτοτύπου: Κατασκευάστε πρωτότυπα χρησιμοποιώντας μεθόδους ταχείας πρωτοτυποποίησης.

- Δοκιμές υλικών: Δοκιμή για αντοχή, αντοχή σε κόπωση και ανθεκτικότητα.

- Ανάπτυξη διαδικασιών παραγωγής:

- Σχεδιασμός διαδικασιών: Σχεδιάστε τα στάδια κατασκευής και τον ποιοτικό έλεγχο.

- Σχεδιασμός εργαλείων: Δημιουργήστε ακριβή εργαλεία και μήτρες.

- Πιλοτική παραγωγή: Δοκιμάστε τη διαδικασία κατασκευής με πιλοτικές εκτελέσεις.

- Έλεγχος και διασφάλιση ποιότητας:

- Επιθεώρηση: Δημιουργήστε αυστηρά πρωτόκολλα επιθεώρησης.

- Έλεγχος διεργασιών: Χρήση στατιστικών τεχνικών για τη διατήρηση της ποιότητας.

- Μη καταστροφικός έλεγχος: Ελέγξτε για εσωτερικά ελαττώματα χωρίς ζημιές.

- Δοκιμή επιδόσεων και επικύρωση:

- Λειτουργικές δοκιμές: Δοκιμή σε πραγματικές συνθήκες.

- Δοκιμές κραδασμών και θορύβου: Βεβαιωθείτε ότι δεν υπάρχουν ασυνήθιστοι κραδασμοί ή θόρυβοι.

- Ανάλυση αποτυχίας: Εντοπισμός και επιδιόρθωση ζητημάτων σε μη συμμορφούμενα εξαρτήματα.

- Τελική παραγωγή και έναρξη:

- Παραγωγή πλήρους κλίμακας: Μετακίνηση σε μεγάλης κλίμακας παραγωγή με ποιοτικό έλεγχο.

- Συσκευασία και αποστολή: Εξασφαλίστε ασφαλή και επισημασμένη συσκευασία.

- Ανατροφοδότηση πελατών: Συλλέξτε και αναλύστε τα σχόλια για βελτιώσεις.

- Συνεχής βελτίωση:

- Ε&Α: Συνεχής καινοτομία και βελτίωση των σχεδίων.

- Εκπαίδευση: Ενημέρωση του προσωπικού για τις τελευταίες τεχνολογίες.

- Υποστήριξη πελατών: Παροχή ισχυρής υποστήριξης και γρήγορη αντιμετώπιση των προβλημάτων.

Ακολουθώντας αυτές τις διαδικασίες ανάπτυξης, οι τεντωτήρες υψηλής ακρίβειας κατασκευάζονται για να πληρούν αυστηρά πρότυπα, εξασφαλίζοντας αξιόπιστη απόδοση και μακροζωία στις αντίστοιχες εφαρμογές τους.

Επικοινωνήστε μαζί μας εάν έχετε οποιεσδήποτε ερωτήσεις ή απαιτήσεις.