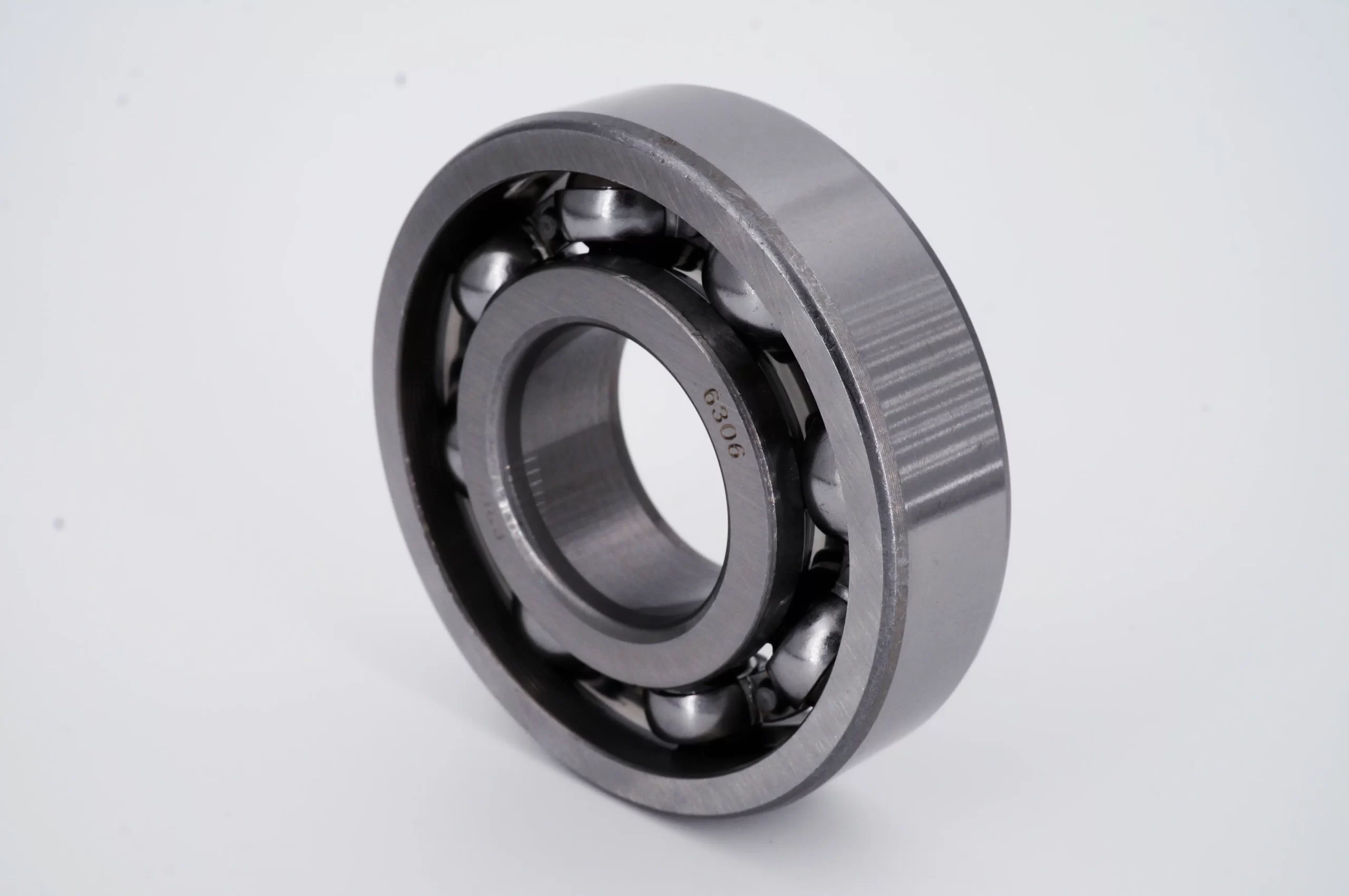

Σειρά ρουλεμάν με βαθύ αυλάκι 6300: Διασφάλιση ποιότητας και συμβουλές συντήρησης

Πλεονεκτήματα του ρουλεμάν με βαθύ αυλάκι 6300 Series

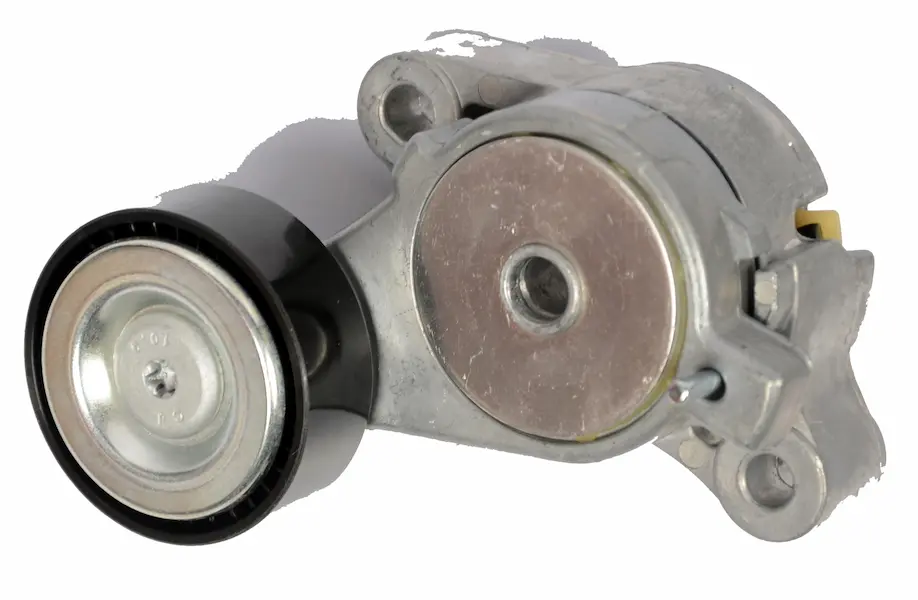

Η σειρά 6300 των ρουλεμάν με βαθύ αυλάκι αναγνωρίζεται για τις εξαιρετικές επιδόσεις και την αξιοπιστία της, προσφέροντας σημαντικά πλεονεκτήματα σε ένα ευρύ φάσμα εφαρμογών. Αυτά τα ρουλεμάν έχουν σχεδιαστεί για να διαχειρίζονται ταυτόχρονα σημαντικά ακτινικά και αξονικά φορτία, χάρη στη στιβαρή κατασκευή τους. Αυτό τα καθιστά κατάλληλα για απαιτητικές εφαρμογές σε διάφορες βιομηχανίες, από την αυτοκινητοβιομηχανία και τον βιομηχανικό εξοπλισμό έως τις οικιακές συσκευές.

Ένα από τα βασικά χαρακτηριστικά της σειράς 6300 είναι η υψηλή ικανότητα φόρτωσης. Τα ρουλεμάν έχουν σχεδιαστεί για να υποστηρίζουν σημαντικές δυνάμεις, εξασφαλίζοντας ότι μπορούν να αντέξουν μεγάλα φορτία χωρίς να διακυβεύεται η λειτουργικότητά τους. Αυτό το χαρακτηριστικό είναι ζωτικής σημασίας για εφαρμογές που απαιτούν από τα ρουλεμάν να διαχειρίζονται αποτελεσματικά τόσο τις ακτινικές όσο και τις αξονικές καταπονήσεις.

Επιπλέον, τα ρουλεμάν της σειράς 6300 είναι βελτιστοποιημένα για λειτουργίες υψηλής ταχύτητας. Ο σχεδιασμός τους με χαμηλή τριβή ελαχιστοποιεί την παραγωγή θερμότητας, επιτρέποντάς τους να λειτουργούν ομαλά και αποτελεσματικά ακόμη και σε υψηλές ταχύτητες. Αυτό είναι ιδιαίτερα σημαντικό για εφαρμογές που περιλαμβάνουν ακριβείς και γρήγορες περιστροφές, όπου η ομαλή και αποδοτική απόδοση είναι απαραίτητη.

Η ανθεκτικότητα είναι ένα άλλο χαρακτηριστικό γνώρισμα της σειράς 6300. Αυτά τα ρουλεμάν είναι κατασκευασμένα για να αντέχουν σε δύσκολες συνθήκες λειτουργίας, εξασφαλίζοντας μεγάλη διάρκεια ζωής και σταθερή απόδοση για μεγάλα χρονικά διαστήματα. Αυτή η ανθεκτικότητα μειώνει την ανάγκη για συχνές αντικαταστάσεις, καθιστώντας τα μια οικονομικά αποδοτική επιλογή για διάφορες εφαρμογές.

Η ευελιξία της σειράς 6300 είναι αξιοσημείωτη. Αυτά τα ρουλεμάν μπορούν να χρησιμοποιηθούν σε ένα ευρύ φάσμα βιομηχανιών και μηχανημάτων. Η προσαρμοστικότητά τους σε διαφορετικές εφαρμογές τα καθιστά πολύτιμο εξάρτημα στην αυτοκινητοβιομηχανία, τη βιομηχανία και το οικιακό περιβάλλον, αναδεικνύοντας την ευρεία χρηστικότητά τους.

Επιπλέον, τα ρουλεμάν της σειράς 6300 είναι σχεδιασμένα για χαμηλή συντήρηση. Απαιτούν μόνο περιστασιακή λίπανση, χάρη στη στεγανή τους σχεδίαση που συχνά αποτρέπει την είσοδο ρύπων. Αυτό το χαρακτηριστικό μειώνει τις προσπάθειες συντήρησης και το σχετικό κόστος, καθιστώντας τα μια πρακτική επιλογή τόσο για εφαρμογές υψηλής ζήτησης όσο και για τυπικές εφαρμογές.

Τέλος, η ομαλή λειτουργία είναι ένα βασικό πλεονέκτημα της σειράς 6300. Αυτά τα ρουλεμάν έχουν σχεδιαστεί για να λειτουργούν αθόρυβα και αποτελεσματικά, γεγονός που συμβάλλει στη μείωση του θορύβου και των κραδασμών. Αυτό έχει ως αποτέλεσμα ένα πιο άνετο και σταθερό περιβάλλον μηχανής, βελτιώνοντας τη συνολική λειτουργική απόδοση.

Συνοπτικά, τα ρουλεμάν με βαθύ αυλάκι της σειράς 6300 προσφέρουν υψηλή χωρητικότητα φορτίου, δυνατότητα υψηλών ταχυτήτων, ανθεκτικότητα, ευελιξία, χαμηλή συντήρηση και ομαλή λειτουργία. Αυτά τα χαρακτηριστικά τα καθιστούν αξιόπιστη επιλογή για ένα ευρύ φάσμα εφαρμογών, εξασφαλίζοντας βέλτιστη απόδοση και μακροζωία.

Διασφάλιση ποιότητας στην παραγωγή

Η διασφάλιση της ποιότητας των ρουλεμάν με βαθύ αυλάκι είναι υψίστης σημασίας για την απόδοση και την αξιοπιστία τους. Το εργοστάσιό μας εφαρμόζει μια αυστηρή διαδικασία πολλαπλών σταδίων για τη διατήρηση υψηλών προτύπων:

- Προμήθεια υλικών και αρχικές επιθεωρήσεις:

- Υλικά υψηλής ποιότητας: Ξεκινάμε με την προμήθεια υλικών υψηλής ποιότητας, που είναι ζωτικής σημασίας για την απόδοση του ρουλεμάν. Κάθε παρτίδα υποβάλλεται σε ενδελεχή έλεγχο για να εξακριβωθεί η συμμόρφωσή της με τα πρότυπα ποιότητας. Αυτό περιλαμβάνει ανάλυση χημικής σύνθεσης και μηχανικές δοκιμές για να διασφαλιστεί η καταλληλότητα του υλικού.

- Κατασκευή ακριβείας:

- Τεχνικές κατεργασίας: Χρησιμοποιούνται προηγμένες τεχνικές κατεργασίας για την επίτευξη ακριβών διαστάσεων και ανοχών. Η συνεχής παρακολούθηση κατά τη διάρκεια της παραγωγής διασφαλίζει ότι κάθε ρουλεμάν διατηρεί τις ακριβείς προδιαγραφές.

- Ακρίβεια διαστάσεων: Πραγματοποιούνται τακτικοί έλεγχοι και βαθμονομήσεις στα μηχανήματα για την τήρηση αυστηρών προτύπων διαστάσεων.

- Θερμική επεξεργασία:

- Ελεγχόμενες διεργασίες: Τα ρουλεμάν υποβάλλονται σε θερμική επεξεργασία για την ενίσχυση της σκληρότητας και της αντοχής τους. Η διαδικασία επεξεργασίας ελέγχεται προσεκτικά, με ακριβή παρακολούθηση των θερμοκρασιών και των ρυθμών ψύξης για την επίτευξη σταθερών αποτελεσμάτων.

- Δοκιμές επιδόσεων: Μετά τη θερμική κατεργασία, τα ρουλεμάν ελέγχονται για σκληρότητα ώστε να διασφαλιστεί ότι πληρούν τις απαιτούμενες προδιαγραφές.

- Επιθεώρηση και δοκιμή:

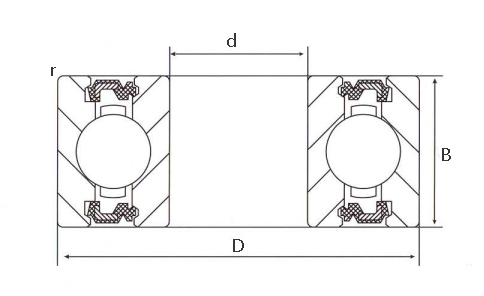

- Έλεγχοι διαστάσεων: Κάθε ρουλεμάν ελέγχεται ως προς την ακρίβεια των διαστάσεων, συμπεριλαμβανομένων των εσωτερικών και εξωτερικών διαμέτρων του δακτυλίου και των μεγεθών των σφαιρών.

- Φινίρισμα επιφάνειας: Πραγματοποιούνται αξιολογήσεις για να εξασφαλιστεί ένα ομαλό φινίρισμα της επιφάνειας, μειώνοντας την τριβή και τη φθορά.

- Δοκιμές φορτίου και ταχύτητας: Τα ρουλεμάν υποβάλλονται σε προσομοιωμένες συνθήκες λειτουργίας για να δοκιμαστεί η ικανότητα φόρτωσης και η απόδοση ταχύτητας.

- Καθαρισμός και λίπανση: Τα ρουλεμάν καθαρίζονται σχολαστικά για την απομάκρυνση τυχόν ρύπων και στη συνέχεια λιπαίνονται με τον συνιστώμενο τύπο και ποσότητα λιπαντικού.

- Συσκευασία και παράδοση:

- Συσκευασία: Τα ρουλεμάν συσκευάζονται με προσοχή για την προστασία τους κατά την αποθήκευση και τη μεταφορά. Χρησιμοποιούνται κατάλληλα υλικά συσκευασίας για την αποφυγή επιμολύνσεων και φυσικών ζημιών.

- Χειρισμός: Ακολουθούνται αυστηρές διαδικασίες χειρισμού για να διασφαλιστεί ότι τα ρουλεμάν φτάνουν σε βέλτιστη κατάσταση.

Συμβουλές για την εγκατάσταση και τη συντήρηση

Για να μεγιστοποιήσετε την απόδοση και τη διάρκεια ζωής των ρουλεμάν με βαθύ αυλάκι, λάβετε υπόψη τις παρακάτω συμβουλές για την εγκατάσταση και τη συντήρηση:

- Σωστή εγκατάσταση:

- Χρήση σωστών εργαλείων: Βεβαιωθείτε ότι τα ρουλεμάν εγκαθίστανται με τα κατάλληλα εργαλεία και τεχνικές για την αποφυγή ζημιών. Ακολουθήστε τις προδιαγραφές του κατασκευαστή για τη ροπή και την ευθυγράμμιση.

- Αποφύγετε την υπερβολική βία: Η άσκηση υπερβολικής δύναμης κατά την εγκατάσταση μπορεί να βλάψει το ρουλεμάν ή τα εξαρτήματά του. Τηρείτε τις συνιστώμενες διαδικασίες για να διασφαλίσετε τη σωστή εγκατάσταση.

- Τακτική λίπανση:

- Προδιαγραφές: Χρησιμοποιήστε τον συνιστώμενο τύπο και την ποσότητα λιπαντικού που καθορίζεται από τον κατασκευαστή. Ελέγχετε και αναπληρώνετε τακτικά το λιπαντικό για να διατηρήσετε τη βέλτιστη απόδοση.

- Εξασφάλιση καθαριότητας: Διατηρείτε το λιπαντικό καθαρό και απαλλαγμένο από ρύπους για να αποφύγετε τη ζημιά στο ρουλεμάν.

- Σωστή εφαρμογή και ευθυγράμμιση:

- Ελέγξτε την εφαρμογή: Βεβαιωθείτε ότι το ρουλεμάν εφαρμόζει σωστά στο περίβλημά του και στον άξονα για να αποφευχθεί η κακή ευθυγράμμιση. Ελέγχετε τακτικά για ενδείξεις κακής ευθυγράμμισης, οι οποίες μπορεί να οδηγήσουν σε ανομοιόμορφη φθορά και πρόωρη βλάβη.

- Εργαλεία ακριβείας: Χρησιμοποιήστε εργαλεία ακριβείας για να μετρήσετε και να ρυθμίσετε την ευθυγράμμιση όπως απαιτείται.

- Σωστός χειρισμός:

- Χειριστείτε με προσοχή: Αποφύγετε τις φυσικές ζημιές κατά τη μεταφορά και την εγκατάσταση. Χρησιμοποιήστε καθαρά γάντια για να αποφύγετε τη μόλυνση από λάδια και ρύπους.

- Αποφύγετε τις σταγόνες: Αποφεύγετε να ρίχνετε ή να χτυπάτε το ρουλεμάν, καθώς αυτό μπορεί να προκαλέσει βαθουλώματα και να επηρεάσει την απόδοση.

- Προστασία του περιβάλλοντος:

- Προστασία από μολυσματικούς παράγοντες: Προστατεύστε το ρουλεμάν από τη βρωμιά, τη σκόνη και την υγρασία που μπορεί να προκαλέσουν διάβρωση και φθορά. Χρησιμοποιήστε κατάλληλες σφραγίδες και ασπίδες για να αποτρέψετε την είσοδο ρύπων.

- Αποθήκευση: Αποθηκεύστε τα ρουλεμάν σε καθαρό, ξηρό περιβάλλον για να τα προστατεύσετε από περιβαλλοντικούς παράγοντες.

- Τακτική επιθεώρηση:

- Διεξαγωγή επιθεωρήσεων: Πραγματοποιείτε τακτικούς ελέγχους για να εντοπίζετε έγκαιρα φθορά, ζημιές ή άλλα προβλήματα. Αναζητήστε μη φυσιολογικούς θορύβους, δονήσεις ή μεταβολές της θερμοκρασίας που μπορεί να υποδεικνύουν προβλήματα.

- Αντικαταστήστε ανάλογα με τις ανάγκες: Αντικαταστήστε τα ρουλεμάν που παρουσιάζουν σημάδια φθοράς ή ζημιάς για να αποφύγετε πιθανές βλάβες.

Ακολουθώντας αυτές τις οδηγίες και διατηρώντας αυστηρό ποιοτικό έλεγχο, μπορείτε να εξασφαλίσετε τη βέλτιστη απόδοση και μακροζωία των ρουλεμάν σας με βαθύ αυλάκι. Η τακτική συντήρηση, ο προσεκτικός χειρισμός και η τήρηση των βέλτιστων πρακτικών θα βοηθήσουν στην πρόληψη κοινών προβλημάτων και θα εξασφαλίσουν ομαλή, αξιόπιστη λειτουργία σε διάφορες εφαρμογές.