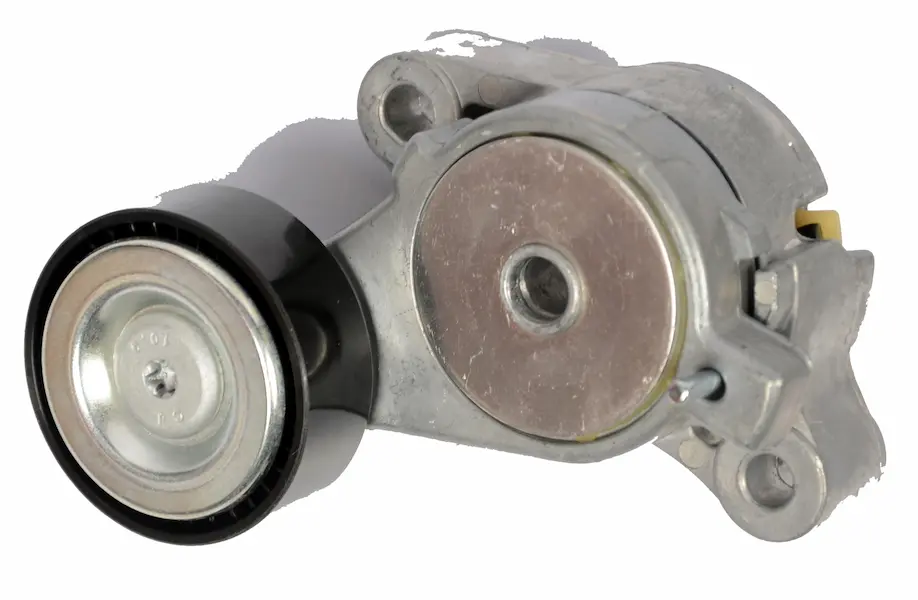

Vores strammer- og tomgangsremskiver er designet til at opfylde de høje standarder for Volkswagen (VW) og Audi køretøjer, hvilket sikrer optimal ydeevne og holdbarhed.

Disse komponenter er konstrueret med præcision for at opfylde eller overgå OEM-specifikationer, hvilket giver pålidelig drift og holdbarhed.

Vi er forpligtet til at producere strammer- og tomgangsremskiver af høj kvalitet, der leverer pålidelighed og ydeevne til VW- og Audi-biler.

Disse komponenter er fremstillet med fokus på holdbarhed og præcision og sikrer ensartet spænding og justering af motorremme, hvilket forbedrer effektiviteten og levetiden.

Udforsk vores engagement i kvalitetshåndværk. Du er velkommen til at kontakte os, uanset hvilke krav du har.

Biler fra Volkswagen (VW) og Audi er kendt for deres fremragende teknik, pålidelighed og ydeevne.

For at sikre, at disse køretøjer kører problemfrit, er det nødvendigt med komponenter af høj kvalitet, herunder strammeren og tomgangsskiverne.

Vores strammer- og tomgangsremskiver er specielt designet til at opfylde de krævende standarder for VW og Audi, hvilket giver optimal ydelse og holdbarhed.

Strammeren sørger for, at drivremmene holder den korrekte spænding, så de ikke glider og sikrer effektiv drift af motortilbehør som generator, vandpumpe og servostyringspumpe.

Ved at udstyre den med en mekanisme som f.eks. en fjeder, tilpasser strammeren sig automatisk til variationer i remspændingen, hvilket sikrer en ensartet ydelse i hele remmens levetid.

Tomgangsskiven styrer drivremmen rundt om motorens tilbehør og sikrer, at den følger den rigtige vej og opretholder en korrekt justering.

Ved at opretholde en korrekt justering og spænding af remmen sikrer tomgangsskiven en effektiv drift af remtrækssystemet.

Både vores strammer og tomgangsskive er produceret med nøjagtige specifikationer, så de passer perfekt til VW- og Audi-motorer.

Vores strammer- og tomgangsremskiver sikrer, at VW- og Audi-motorer kører jævnt og effektivt og opretholder den ydeevne, som disse mærker er kendt for.

Vi er dedikerede til at producere strammer- og tomgangsremskiver, der overgår VW- og Audi-ejernes forventninger.

Vores investering i højkvalitetsforme og præcisionsfremstilling sikrer, at hver remskive, vi producerer, er af højeste kvalitet og giver pålidelighed og ydeevne, som du kan stole på.

Tips til vedligeholdelse af strammere

- Regelmæssige inspektioner:

- Visuel kontrol: Efterse jævnligt strammeren for tegn på slitage, f.eks. revner, korrosion eller skader.

- Bæltets tilstand: Kontrollér serpentinen eller tandremmen for slid, revner, glasering eller flosser, da disse kan påvirke strammerens ydeevne.

- Lyt efter usædvanlige lyde:

- Skrigende eller raslende lyd: Usædvanlige lyde kan være tegn på en defekt strammer eller en fejljusteret rem. Gør noget ved disse lyde med det samme for at forhindre yderligere skader.

- Tjek spændebåndets justering:

- Korrekt justering: Sørg for, at strammeren er korrekt justeret i forhold til remmen. Forkert justering kan forårsage overdreven slitage på remmen og andre komponenter.

- Test bæltespændingen:

- Korrekt spænding: Brug en remspændingsmåler til at kontrollere, at remspændingen er inden for producentens angivne område. Juster om nødvendigt.

- Automatiske strammere: Sørg for, at de automatiske spændere fungerer korrekt og giver den rigtige spænding.

- Smøring:

- Producentens anbefalinger: Følg producentens retningslinjer for smøring. Nogle strammere er forsmurte og forseglede og kræver ingen yderligere smøring.

- Udskift efter behov:

- Serviceintervaller: Udskift strammeren i henhold til bilproducentens anbefalede serviceintervaller, eller hvis der opdages tegn på fejl.

- Samtidig udskiftning: Overvej at udskifte remmen og andre relaterede komponenter (som f.eks. tomgangsskiven), når du udskifter strammeren for at sikre optimal ydelse.

- Rengør området:

- Fri for affald: Hold strammeren og det omgivende område fri for snavs, skidt og olie for at forhindre forurening og sikre problemfri drift.

- Overvåg motorens ydeevne:

- Motorens adfærd: Vær opmærksom på motorens ydeevne. Symptomer som glidende remme, overophedning eller krafttab kan være tegn på problemer med strammerne.

- Brug kvalitetsdele:

- OEM-dele: Brug OEM-dele (Original Equipment Manufacturer) eller eftermarkedsdele af høj kvalitet for at sikre kompatibilitet og pålidelighed.

- Professionel inspektion:

- Mekanikertjek: Få en professionel mekaniker til at inspicere strammeren og bæltesystemet ved regelmæssige servicebesøg for at fange eventuelle problemer tidligt.

Ved at følge disse vedligeholdelsestips kan du forlænge strammerens levetid, sikre en pålidelig drift af bilens remtræk og forhindre uventede nedbrud.