Натегачите са критични компоненти в автомобилните системи, внимателно проектирани за поддържане на правилното натягане на ремъците на основни части на двигателя като алтернатори, водни помпи и компресори на климатика. Тези компоненти гарантират, че ремъците остават оптимално опънати, предотвратявайки приплъзване и износване, което може да доведе до механична повреда и намаляване на ефективността.

Механизми и значение

Напрегнателите използват усъвършенствани механизми като пружини или хидравлика, за да осигурят постоянно напрежение. Обикновено се използват пружинни обтегачи, тъй като те осигуряват постоянен натиск върху ремъка, като автоматично се настройват за разтягане и износване на ремъка с течение на времето. Хидравличните обтегачи, от друга страна, използват налягане на течност за поддържане на напрежението и могат да бъдат по-издръжливи в среди с висока температура. И двата вида обтегачи играят жизненоважна роля за повишаване на издръжливостта на ремъка и оперативната ефективност, като гарантират, че ремъците не са прекалено хлабави или прекалено опънати, което в противен случай може да доведе до преждевременна повреда.

Дизайн на повърхността и намаляване на триенето

Конструкцията на обтяжните ролки е от решаващо значение. Те са с гладка повърхност, за да се сведе до минимум триенето, което е от съществено значение за поддържане на надеждността и максималната производителност на двигателите на автомобилите. Гладката повърхност гарантира, че ремъкът се плъзга без усилие по ремъчната шайба, което намалява износването. Тази конструктивна особеност спомага за удължаването на живота както на ремъка, така и на ролката, като гарантира безпроблемната работа на компонентите на двигателя за продължителни периоди от време.

Разлика между обтегач и ролки за навиване

За разлика от обтегачите, празните ролки не регулират напрежението, но играят важна роля за поддържане на точното подравняване и безпроблемното функциониране на пътя на ремъка. Направляващите ролки обикновено са фиксирани и служат за водене на ремъка около препятствия и за осигуряване на правилното му движение през компонентите на двигателя. Те са оборудвани със здрави лагери или втулки, които поддържат плавното въртене и поддържат постоянното подравняване на ремъка, като по този начин повишават стабилността и надеждността на системата при продължителна употреба. Правилното подравняване е от решаващо значение, тъй като неправилното подравняване може да доведе до неравномерно износване на ремъка и потенциална повреда на ремъка.

Осигуряване на качеството и обратна връзка с клиентите

Нашите прецизни форми гарантират точността на продуктите ни, а цялостната ни производствена система гарантира качеството. Висококачествените матрици са от съществено значение за производството на обтегачи и ролки, които отговарят на строги допуски и спецификации. Освен това събираме и анализираме обратна връзка от клиентите, за да идентифицираме всякакви проблеми с обтегачите и празните ремъци. Тази обратна връзка е безценна за непрекъснатото усъвършенстване, като ни позволява да усъвършенстваме нашите процеси и продукти въз основа на данни за реална употреба и производителност. Като се вслушваме в нашите клиенти, можем да правим целенасочени корекции, които подобряват надеждността и производителността на продуктите.

Приложения в различни превозни средства

Нашите обтегачи и ремъчни шайби се използват в различни превозни средства, включително:

- Пътнически автомобили: Осигурява надеждна и тиха работа при ежедневна употреба. В леките автомобили добре функциониращата система на коланите е от решаващо значение за осигуряване на плавно и комфортно шофиране.

- Търговски превозни средства: Осигурява издръжливост и ефективност за тежки приложения. Търговските превозни средства, като камиони и автобуси, работят при по-взискателни условия и изискват компоненти, които могат да издържат на по-високи нива на натоварване и износване.

Нашите предимства

- Надеждност: Проектирани да издържат на тежки условия и да осигуряват надеждна работа. Нашите продукти са създадени, за да издържат дълго време, дори в най-предизвикателните условия.

- Разходно ефективен: Дълготрайните компоненти намаляват нуждата от честа подмяна, което спестява пари в дългосрочен план. Като инвестират в качествени компоненти, клиентите могат да намалят разходите за поддръжка и времето за престой.

- Осигуряване на качеството: Всеки продукт преминава през строги тестове, за да отговори на нашите високи стандарти за качество и ефективност. Процесите ни на изпитване гарантират, че всяка ролка отговаря на или надхвърля индустриалните стандарти.

- Експертна поддръжка: Нашият екип от експерти е на разположение за всякакви въпроси, за да ви гарантира, че получавате правилния продукт за вашите нужди. Осигуряваме техническа поддръжка и насоки, за да помогнем на клиентите да изберат най-добрите продукти за техните специфични приложения.

- Конкурентно ценообразуване: Ние предлагаме първокласни продукти на конкурентни цени, като осигуряваме отлична стойност на вашата инвестиция. Нашата цел е да доставяме висококачествени продукти, които са на достъпни цени.

Ангажимент за съвършенство

Стремим се да доставяме продукти, които надхвърлят очакванията на нашите клиенти. Инвестициите ни във висококачествени матрици и прецизно производство гарантират, че всяка произведена от нас ролка е с най-високо качество, осигурявайки надеждност и производителност, на които можете да се доверите. Вярваме в непрекъснатото усъвършенстване и иновациите, като постоянно търсим начини за подобряване на нашите продукти и процеси.

Защо да изберете нас?

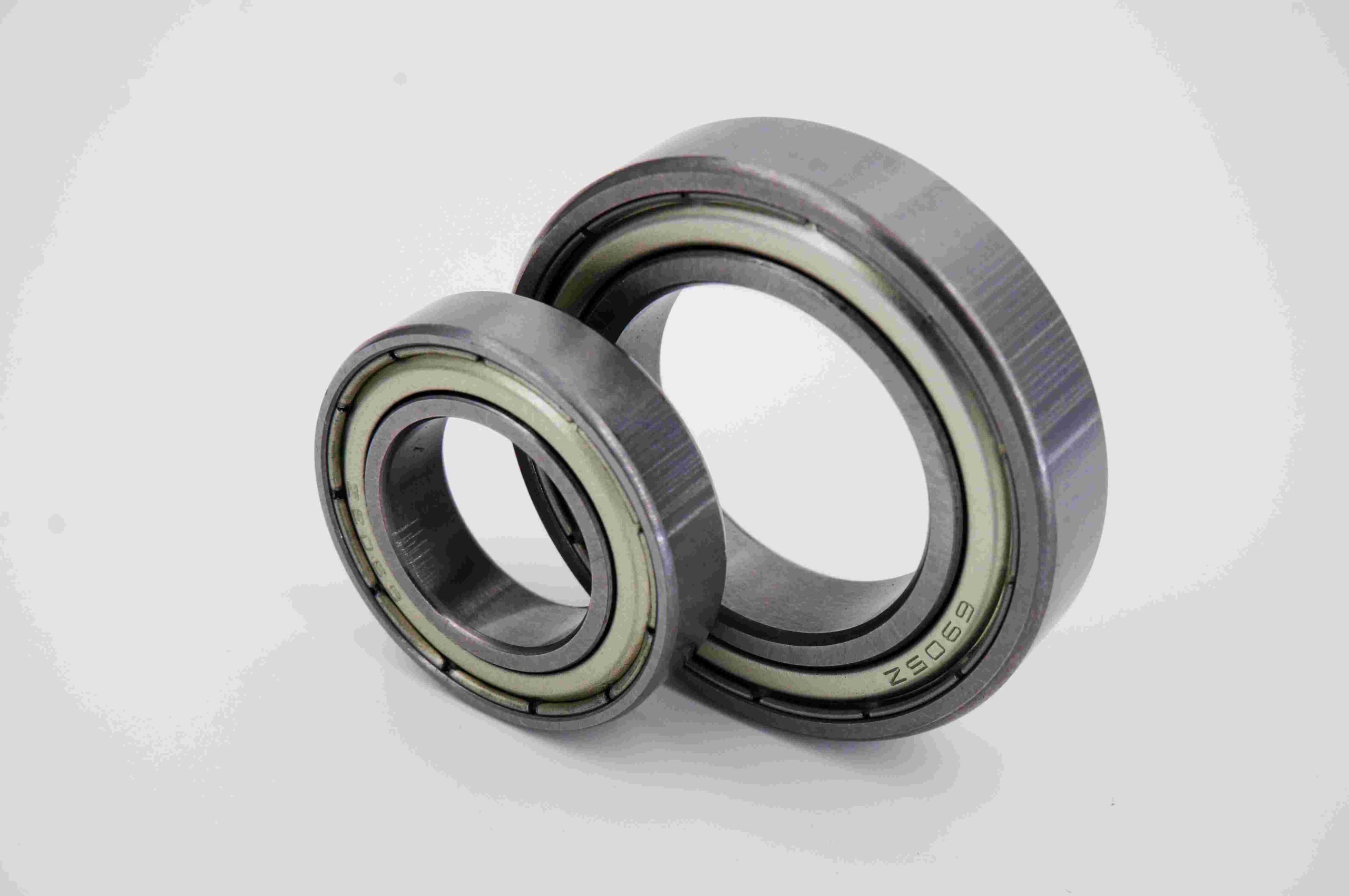

Vankv Wuxi Mechanical Equipment Co., Ltd. е създадена през 2014 г. и е специализирана в производството на сачмени лагери с дълбок жлеб, лагери за водни помпи и лагери за главини на колела. Благодарение на непрекъснатите технологични иновации и модернизираното производствено оборудване нашите лагери се използват в цял свят в различни отрасли, включително автомобилната индустрия, електродвигателите, домакинските уреди, офис оборудването и електрическите инструменти. Нашият екип от инженери постоянно разработва нови продукти, за да предоставя висококачествени услуги на индустрията, и с нетърпение очакваме да си сътрудничим с вас.

Основна бизнес философия

Ръководейки се от основната бизнес философия за "иновации" и "пробив", ние се стремим да разширяваме нашите изследователски и производствени възможности, за да отговорим на променящите се пазарни изисквания, като постоянно въвеждаме усъвършенствани продукти от серията "Vankv". Иновациите са в основата на всичко, което правим, и ни карат да разработваме нови технологии и да подобряваме съществуващите продукти.

Нашият опит

С повече от 10 години в бизнеса с резервни части за автомобили, ние имаме опита да гарантираме, че всички наши продукти са квалифицирани и гарантирани. Богатият ни опит ни позволява да разберем уникалните предизвикателства, пред които са изправени нашите клиенти, и да предоставим персонализирани решения, които отговарят на техните специфични нужди.

Бърза комуникация

Отговаряме на клиентите чрез имейл, WhatsApp или други методи, обикновено в рамките на няколко минути. Бързата и ефективна комуникация е от ключово значение за осигуряването на отлично обслужване на клиентите и гарантиране на тяхната удовлетвореност.

Потребителски опаковки

Предлагаме различни варианти за опаковане, включително торбички с балончета, кашони, дървени кутии, пластмасови кутии и персонализирани стилове. Нестандартните опаковки гарантират, че нашите продукти са защитени по време на транспортирането и пристигат в перфектно състояние.

Безплатна проба

Предоставяме безплатни мостри за артикули на склад (1-2 модела), като разходите за доставка се поемат от клиента. Това позволява на потенциалните клиенти да оценят нашите продукти от първа ръка и да вземат информирани решения за покупка.